Challenge

Landguth Heimtiernahrung, a wet pet food producer, was in need of a better way of monitoring their autoclaves. Their old system had approximately 70 autoclave control systems separated from one another: that meant configuration of those systems needed to be done individually, and they had no centralized information of their processes.

Solution

Landguth had already been using a Rohrbach Elektrotechnik autoclave control system developed with FrameworX for more than 3 years, running as a test autoclave. The new, innovative and robust control concept, the convenience and performance of the process visualization program and the possibility to manage all autoclaves via one central control system showed the kind of improvement they were looking to achieve.

Results

- Reduced risk and error: Automatic checks reduce the number of possible operating errors and the time required to manage the autoclaves compared to the old control system.

- Less downtime: During ongoing production, changes can be made to cooking programs, recipes, or to user administration.

- Availability: All data is immediately available and significantly contributes to the monitoring and optimization of production processes.

“The implementation of FrameworX by Rohrbach Elektrotechnik has enabled us to easily operate and control the autoclaves from a central location. The operability of the autoclaves has greatly improved. In addition, the flexibility of the system is optimal for our requirements.”

— Landguth Heimtiernahrung GmbH

Landguth Heimtiernahrung is a German producer of premium quality pet food for dogs and cats. They transform initial concepts into quality recipes, which are branded by other companies. Their factory in Ihlow, Germany runs approximately 70 autoclaves used for sterilizing cans, pouches, shells, and other containers according to each pet food’s required temperature- and pressure-controlled cooking program.

Their previous control system was based on a software PLC with an integrated visualization system that had become obsolete. It was a stand-alone application, meaning each autoclave had to be configured separately. This resulted in wasted time and no centralized information.

In addition, the previous solution could neither meet the requirements for central control functions nor allow data to be sent or received where needed. However, Landguth needed the modernization to be fast and avoid downtime: the autoclaves had to be retrofitted one by one and immediately put back into operation during ongoing production.

Rohrbach Elektrotechnik rose to the challenge. They utilized FrameworX as the basis for a new architecture and delivered their first application in only four months. The software was used for more than three years as a test autoclave before being expanded to the entire facility due to its innovative control concept, strong visualization performance, and centralized management capability.

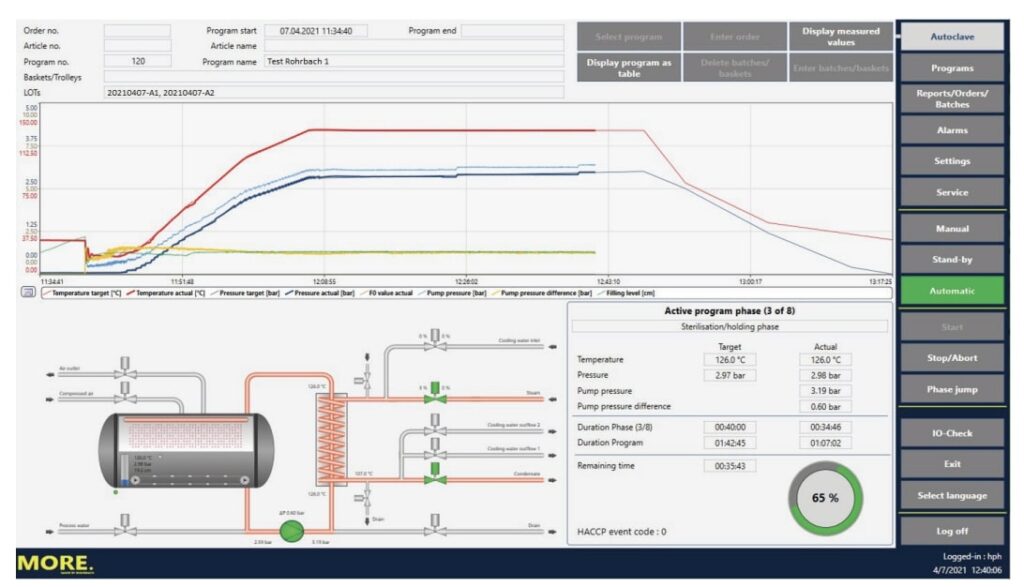

Each autoclave control system consists of a Siemens S7 PLC and an industrial PC with a process visualization system developed in FrameworX. The central control system for managing all autoclaves was also developed using FrameworX, with features such as real-time visualization, alarming, production data, status data, recipe data, and trending.

This project is also defined by its connectivity to other systems: the autoclaves are controlled by a Siemens S7-1500 PLC including Siemens I/O modules, an RFID reader, and a dot-matrix scanner for basket and batch identification — all using the FrameworX integrated Siemens driver to send data quickly and efficiently.

To reduce downtime, implementation was completed quickly on each autoclave. Changes in the central control configuration — cooking programs, user administration, etc. — are automatically transmitted to the autoclaves with one click. Complete production data, machine status, utilization, alarms, event logs, and more are automatically stored in a central SQL database for evaluation and archiving.

Centralized configuration replaces local changes, greatly improving the speed of updates. Centralized data storage enables system comparisons and the development of best practices.

Production Improvements

The end-user reported that new batches complete much more quickly and the autoclaves are now much easier and faster to operate than with the old system.

Changes made during operation, such as adjusting cooking programs or user administration, are now processed automatically, reducing operational errors. Previously, staff had to visit each autoclave with a USB stick.

Now, all data is immediately available, significantly improving monitoring and optimization.

Additional System Enhancements

• Pop-up dialog boxes provide more intuitive process visualization on each autoclave.

• Over 140 operators working 24/7 log in via RFID chips for greater efficiency, reliability, and security.

• Detailed real-time value logging of all sensors allows comprehensive reporting. Graphs provide setpoints and actual values to assess performance and control.

• Analysis of temperature curves enables optimal production adjustments and more responsive leak monitoring.

• Logging of all alarms, parameter changes, and audit trails.

• Automatic PDF generation of production logs for stakeholders.

• Detailed utilization reports help identify downtime and production reserves, resulting in reduced cooking times and quicker unloading.

Data Turned Into Real Information

Operating scale:

70 autoclaves operated 24/7 by 140 operators and supervisors in three shifts.

Tags / communication points:

Each autoclave uses a 1500-point license.

The supervision system uses an unlimited license.

Engineering time:

Rohrbach delivered the first autoclave application in four months.

According to Hans-Peter Hermann, Senior Software Engineer at Rohrbach:

“Leveraging the Code Behind feature in FrameworX displays enabled us to create powerful displays with custom-tailored functional capabilities on a screen-by-screen basis.”