The FrameworX Advantage for OEMs

For Automation Companies & Machine Manufacturers

Tailored or Embedded Solutions for Your Market

Future-Proof Your Machines with FrameworX

Give your machines a competitive edge with FrameworX — a flexible, modern platform purpose-built for OEMs who want to embed powerful SCADA, HMI, IIoT, and Historian capabilities into their equipment. Whether you’re building industrial automation systems, robotics, packaging lines, or mobile machines, our OEM Program helps you deliver smarter products, faster — all under your brand.

Why OEMs Choose Tatsoft FrameworX as Their Platform

Completely Open Architecture

A fully modifiable platform that lets OEMs tailor controls, functionality, and modules—without limitations or vendor lock-in.

Open API Toolkit for Drivers

A complete dev kit for building custom drivers and protocols to support unique hardware and proprietary devices.

Commercially Scalable Licensing

Flexible licensing that scales from PoC to full production, ensuring predictable costs and protecting profit margins.

Adaptable Product Family

From edge HMI to full SCADA and IIoT—one platform supports multiple solutions, reducing dev time and training needs.

Business-Friendly Pricing Structure

Custom pricing models that align with OEM revenue strategies—subscriptions, per-device, or upfront sales.

Full Customization Control

Access to platform modifications and source code allows integration of proprietary features and IP protection.

White-Label Ready

Complete branding control—UI, documentation, deployment—keeping OEMs front and center.

Extensible Technology Foundation

Built on .NET with modular extensibility to support long-term updates and incremental innovation.

Deployment Flexibility

Runs on edge, embedded, on-prem, and cloud—ideal for diverse customer environments.

Partnership Approach

25+ years of OEM collaboration, offering guidance that reduces risk and speeds time-to-market.

What You Can Build with FrameworX

- Embedded HMIs and high-performance machine interfaces

- Web-based portals for remote monitoring and service

- Multi-site dashboards and control panels

- Cloud-ready analytics and historian integration

- Full Unified Namespace (UNS) architectures using MQTT and SparkplugB

- Smart machines with built-in diagnostics and edge logic

Ideal for OEMs in:

- Packaging, bottling, and labeling equipment

- Industrial robotics and motion control systems

- Printing, converting, and flexible packaging lines

- Semiconductor and electronics assembly machines

- Food & beverage production equipment

- Mobile machinery (agriculture, construction, cranes, logistics)

Plug-and-Play Integration

FrameworX connects easily to your control systems and external data platforms:

- PLC support for Siemens, Rockwell, CODESYS, Beckhoff, and more

- MQTT and SparkplugB for modern IIoT messaging

- Native support for OPC UA, REST APIs, SQL databases

- Seamless historian integration with Canary, OSIsoft PI, and cloud storage (Azure, Snowflake, etc.)

What You Get as a Tatsoft OEM Partner

- Deep engineering and onboarding support

- Access to FrameworX SDK and source-code-level APIs

- Custom licensing and deployment models

- Optional co-development and go-to-market collaboration

- A trusted partner to help differentiate your machines with powerful digital capabilities

Some of our OEM Partner Applications

Flow Meter Manufacturer

Advanced Metering solutions on an embedded Linux controller.

Water Analysis Instruments

Protocol converter with real-time calculations on a small form factor Windows 10 IoT PC.

Industrial Computer Company

White label HMI and Andon software for a specialty industrial computer manufacturer.

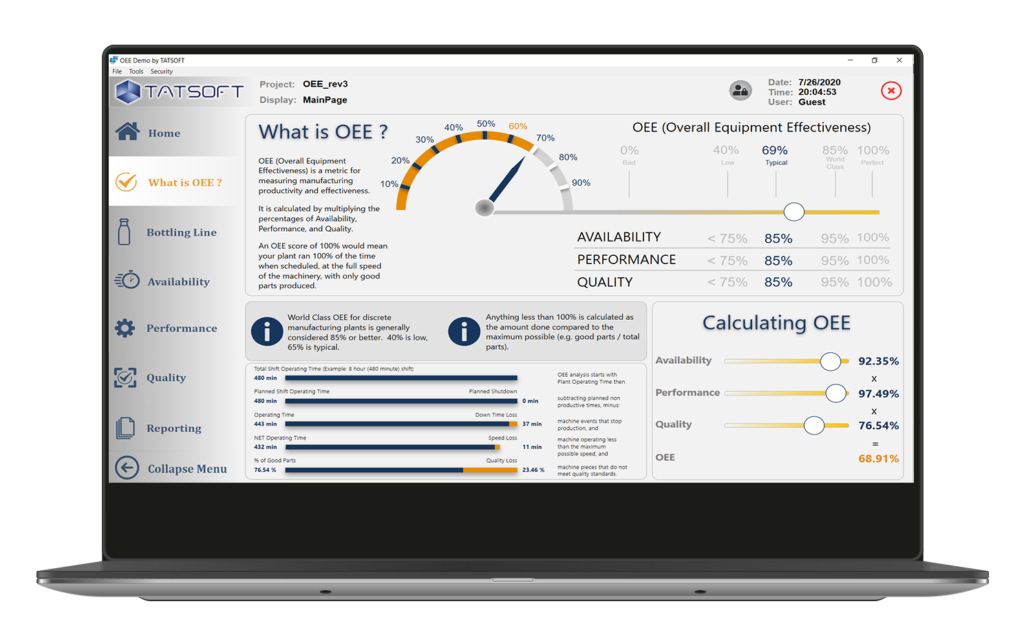

Packaging Machinery

Advanced SCADA / HMI and OEE solution for a packaging machine OEM, moving to a connected IIoT application

Process Analysis

Robust HMI / SCADA system for a leading provider of water treatment and analysis process skids.

Generator Manufacturer

Embedded data collection and analytics on wind power generation equipment OEM.

Featured Case Studies

RigDap solution

Embedded Artificial Intelligence for control, optimization, data aggregation, analytics dashboards for Oil and Gas industry.

Spin Solution

Rapid application development of sophisticated SCADA solution for the Electrical Utilities industry specifically for Transmission and Distribution.

Ready to Learn More?

Let’s explore how FrameworX can elevate your platform.

Contact us for a tailored OEM partnership discussion.