Industry and Partner Solutions

Accelerate your Applications with Partner Solutions

Featured Solutions

Safe, Scalable and Profitable Systems

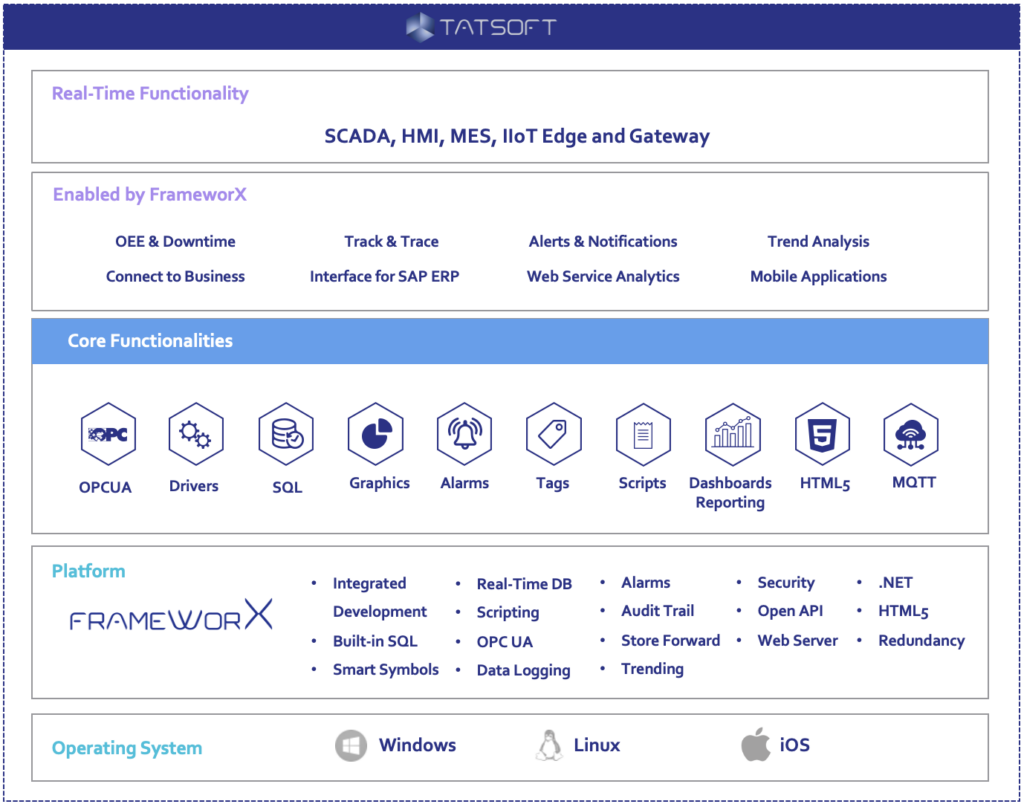

Partner companies use Tatsoft’s software components to create their own automation products addressing specific industry requirements, such as Production Line Monitoring and downtime cause analysis, Drilling Data Aggregation, SCADA for Power and Utilities, Andon displays, and others. End-users and System Integrators are using FrameworX in various industrial segments delivering results for their customers.

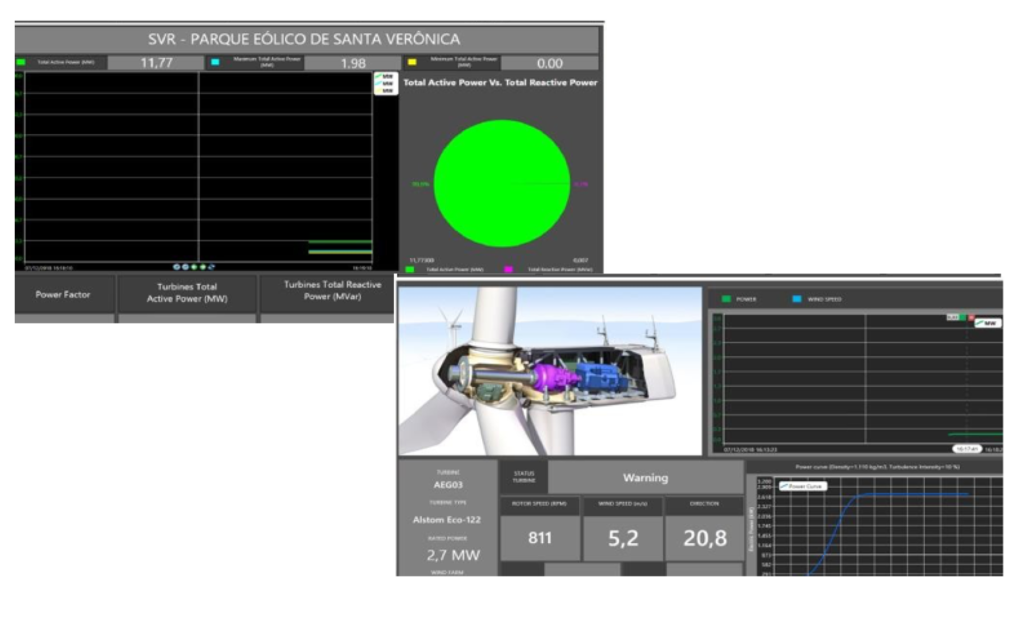

SCADA for Electrical Utilities

Manage, Control and Understand your Electrical Resources

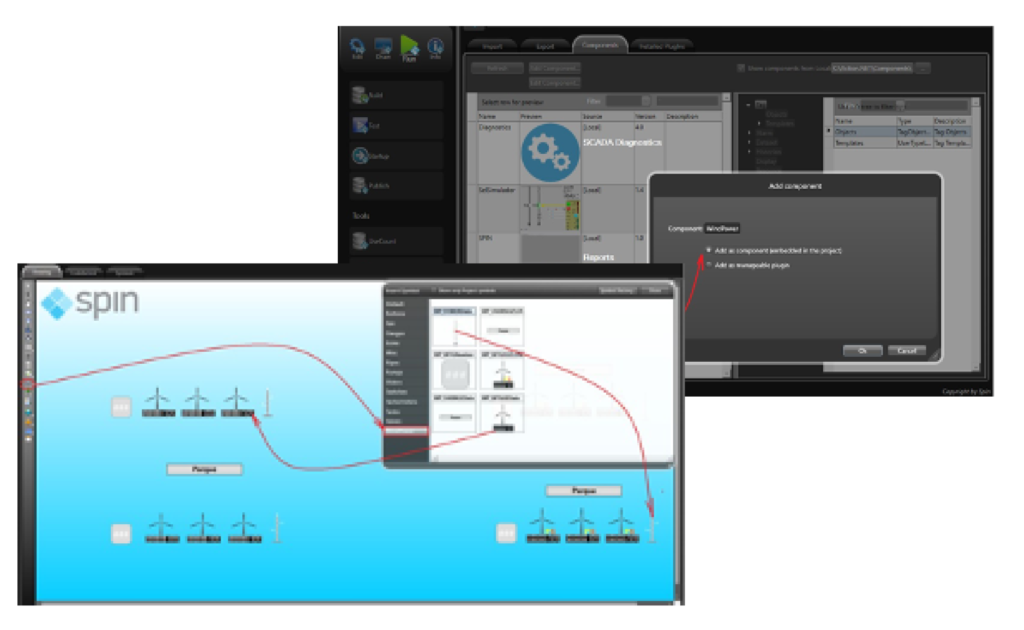

Action.NET by SPIN is a SCADA software built on FrameworX with unique features designed for the energy market. Over 20 years of Spin’s experience in the energy market, with knowledge obtained from over 400 SCADA systems deployed in industrial substations and generation, transmission and distribution companies, combined with Tatsoft’s decades of experience in real-time software, allowed the creation of the ultimate tool for the energy industry, with the most modern elements and focusing on details that only the fieldwork can provide.

Applications spin’s Action.NET enables are specific to power generation around GTD – Generation, Transmission and Distribution.

- Deployed 400+ SCADA systems in Power Plants, Substations, Wind Power, and more

- Created “Lean Automation” with FrameworX to automate and componentize rapid solutions

- Uses FrameworX drivers and worked with Tatsoft to develop built-in communication drivers for DNP 3.0, IEC60870-5

- Solution includes Asset Monitoring Components using FX HTML5 and Store-and-Forward capability

- Great example of a partner that embeds FrameworX into their own solutions as their own brand labeled product

Contact us to learn more.

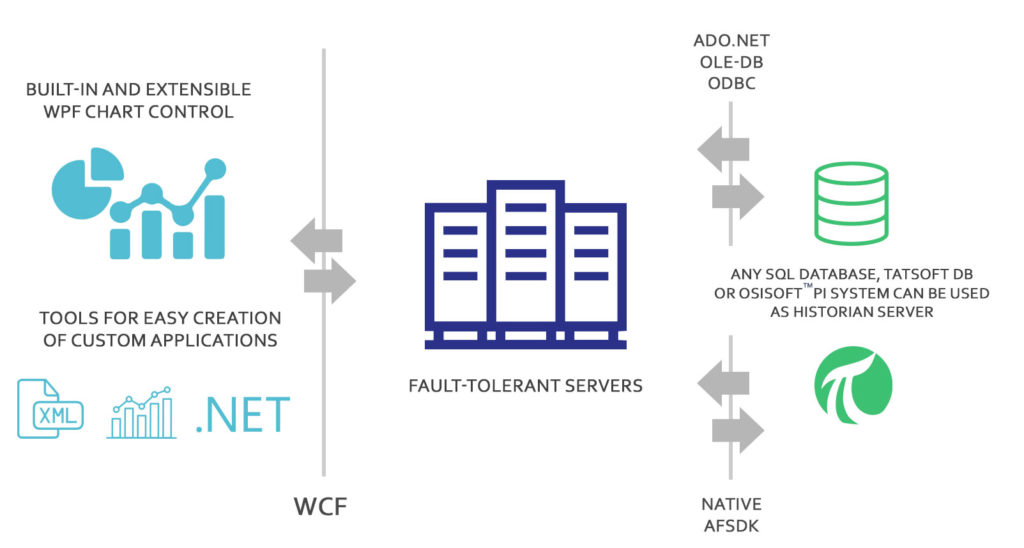

Powerful Tools to enhance OSIsoft PI Applications

Leverage your data, with custom corporate solutions*

*This is available as an option on all FrameworX and FactoryStudio licenses.

Extend access to real-time and historical data through the FrameworX native .NET connection with OSIsoft PI, PI Event Frames, and PI AF servers. Create state-of-the-art custom solutions/applications, combining data from your PI Server and any other data sources (Oracle, SQL, WITSML, etc.). Add custom .NET logic and rich real-time visualization running on desktop thin client, mobile, iOS, or HTML5.

Have your custom projects developed at a fraction of the time and cost.

Leverages the FrameworX tools, creating custom secure applications, using the built-in connections to PI and SQL databases, protocol drivers to PLCs, SNMP, custom logic in .NET languages, graphical designer and all FactoryStudio built-in modules.

Some of the built-in capabilities include:

- Easily combine data to create dynamic real-time displays, from dashboards to SCADA-HMI like displays.

- Use C# or VB.NET scripting PI tags, assets, attributes, SQL queries or calculated data employing Intellisense.

- Powerful trend objects with multiple annotation capabilities: alarm events overlay, annotation by asset or by tag, time-range events, vertical and XY charts and much more.

- Complete Alarm system with acknowledgement control, hierarchical groups and event notification.

- Support for Tags, Templates, Categories, Descriptions, and tree structures created within PI AF.

- Access PI AF definitions for application development and query PI Event Frame servers for batch analysis.

- Create PI points, Assets and read-write data to the PI System or from/to PI AF from FactoryStudio applications

- Direct real-time native integration with the PI System (requires PI System Access License PAL from OSIsoft)

Contact us to learn more.

Industrial Digital Signage

Scoreboards and more

Complete solution to Industrial Digital Signage

Create the ultimate solution for managing and controlling digital signage in industrial environments.

Tatsoft’s tools and solution framework enables manufactures to gain a competitive edge through cost-effective system designs and increased productivity. Typical applications include:

Advanced ANDON Visualization;

Operation Dashboard Builder;

Downtime Analysis & OEE Indicators;

Plant Performance KPI Scoreboards;

Any Display Format -, Mobile, Desktop, Large Display;

Plant Information Management Systems (PIMS).

Contact us to learn more.

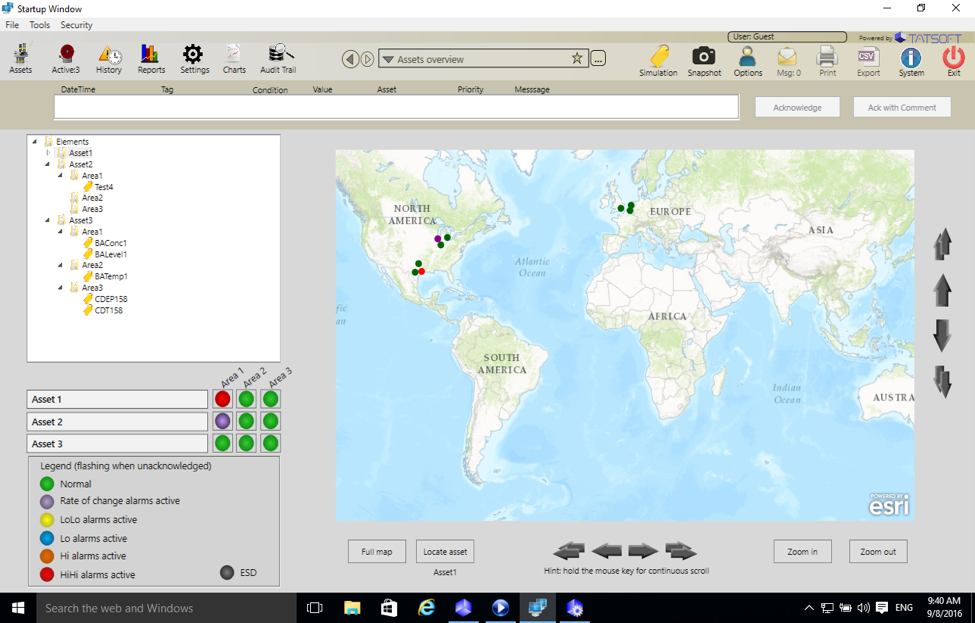

Remote Asset Monitoring

Monitor and audit operations of geographically distributed assets

Our Asset Monitor solution is a template application created on top of FrameworX, allowing the easy implementation of custom corporate applications to monitor and audit operations of remote assets.

Our Asset Monitor solution template project is based on several customer solutions to give you a quick start for your project. It includes:

- Assets Overview Page

- Advanced Trend and Annotations View

- Alarms, Events, and Notifications Engine

- Reports and Dashboard Builder

- Of course, the entire FrameworX Platform development tools

Contact us to learn more.

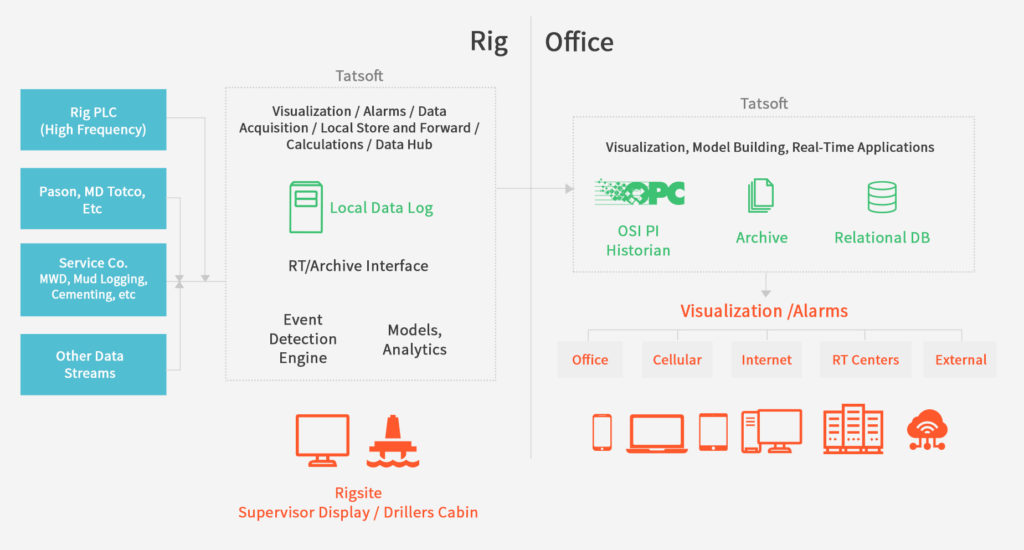

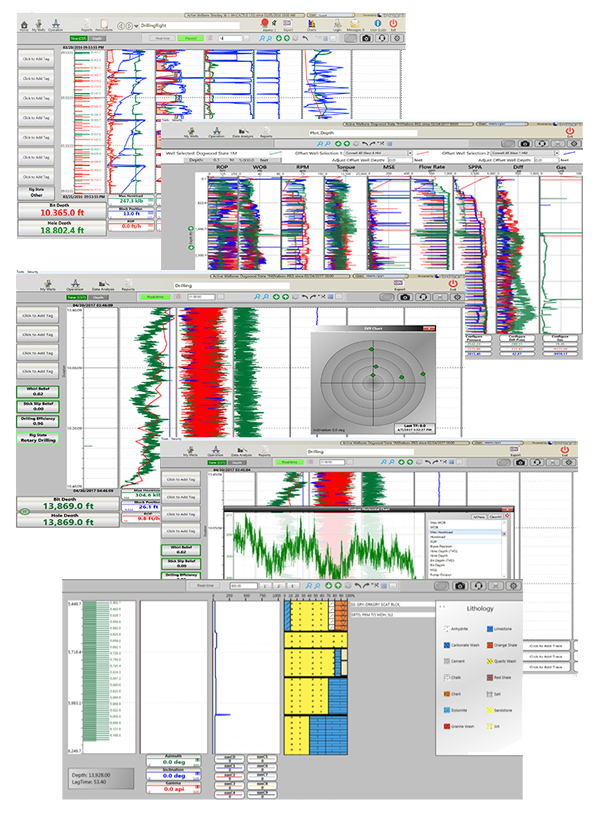

Drilling Rig Data Aggregation - RigDap

Make Data Driven Decisions

Tatsoft’s solution for Drilling Data Aggregation is called RigDap, in combination with our partner, Intellicess and their technology Sentinel RT ™, an A.I. backend engine able to perform real-time streaming-data analysis, allows you to truly own your data so you can perform analysis in a reliable, consistent and controlled way.

Completely Integrated Solution

Our goal is to enable you to make better, faster, data-informed strategic decisions, using real-time data. Tatsoft RM and Sentinel RT™ empower you to increase efficiency, improve performance and drive down well costs.

- Tatsoft Rig Monitoring, Tatsoft RM, collects real-time data from Rigs, on-shore or off-shore locations, connecting with your existing field EDR or directly with the Control Systems, providing a local interface at the Rig and replicating the data to central offices, where it manages the archiving to your long-term data storage, such as OSIsoft PI, Microsoft Azure, Splunk or others.

- Sentinel RT™ adds to this solution by providing real-time streaming-data analysis at the rig or central office, providing uniform source for the raw data. What sets Sentinel RT™ apart from its competition is a highly sophisticated data-cleansing algorithm built upon platform technology that uses a Bayesian network to differentiate between sensor and process faults in complex systems.

- With our solution, you’ll be able to centralize monitoring distributed production assets, with ESRI maps, real-time weather overlay, real-time status of key field variables, advanced trend charts and annotations tool, event notification, with extensive customization capabilities.

Contact us to learn more.

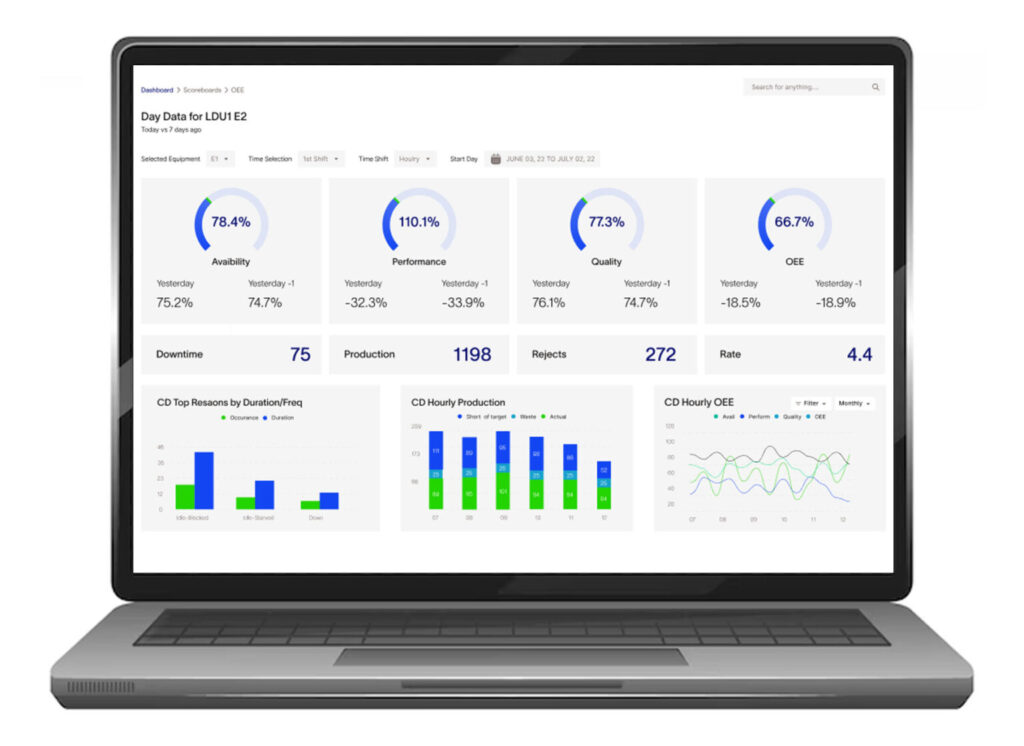

CoreM – Manufacturing Intelligence

Monitor Downtime, Calculate KPIs & OEE, Enter Reason Codes, Track Production, Update ERP and more

CoreM, by INS3, is a software solution that can help you unlock the full performance potential of your manufacturing operations by giving you a real-time understanding of what is happening on your plant floor. Centered around your Plant Model that monitors key events (downtime, quality, material consumption, etc.), CoreM uses FrameworX to present an interactive GUI for reason code entry, key reports, dashboards, and scoreboards.

CoreM Basic Functionality:

- OEE – Downtime, Performance, Quality, Detect, Collect, Manual data entry, update, split, merge, reclassify, Reason Categories, Production Targets, Products, Production Count Tracking, Waste, Waste Counts

- Event Processing Tracking: Production, Downtime, Waste, Batch, Product Change, Tool Change, Generic

- Product Quality: Variables, Specs

- Alerting/Alarming: Escalation, Condition Detection and Messaging (action). Message box, text message, email.

- E-Signature: User and Approver

- Direct link to equipment and/or events and/or users

- Reports, Real-Time Interactive Dashboards- Production, Downtime, Waste, OEE, Variable Quality, Time Context, Shift, Order, Product.

Contact us to learn more.

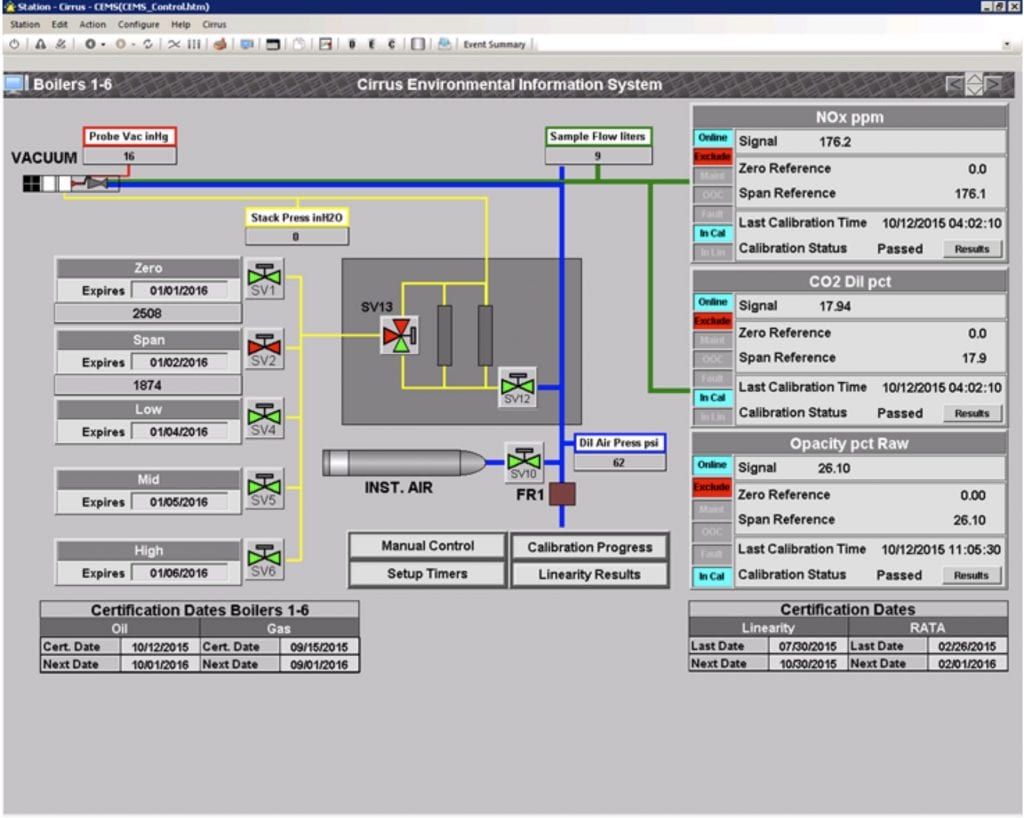

Environmental Information Systems

Environmental management is increasingly complex and depends on quickly gathering, processing, and organizing large amounts of data. Regulators and the public have high expectations about the accuracy and availability of information.

Wunderlich-Malec Engineering’s Environmental Information Systems group has key products to make your regulatory reporting effortless. Whether your facility has a Title V permit, subject to CFR 40, Part 75, Part 60, California RECLAIM, or others, we have a customized solution for you.

Contact us to learn more.