A major oil and gas operator recently upgraded over 250 of its field sites using Tatsoft’s EdgeConnect software, which was installed on Cisco routers and industrial computers.

At each site, EdgeConnect:

– Connected directly to Rockwell and GE control systems

– Organised real-time data locally using a Unified Namespace (UNS)

– Used Python to run on-site checks and alert systems

– Sent data to a central system using MQTT Sparkplug B

– Kept running smoothly even if the internet went down, by saving and forwarding data later

The outcome: The company now gets live updates from each site, has fewer outages, and is ready to use the data for advanced analysis or AI in the future, without depending on extra software or being tied to one vendor.

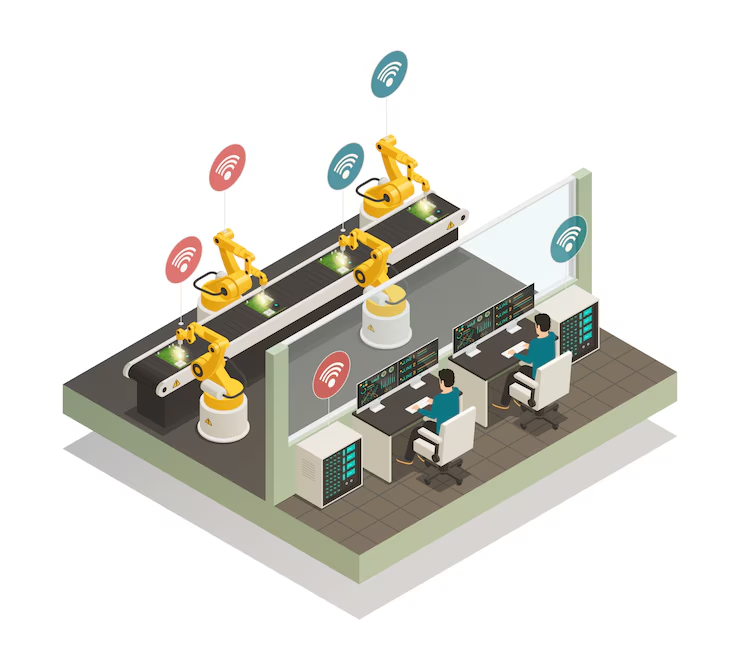

Why Industrial Edge Computing Is Essential

Edge computing is changing industrial automation by bringing computing and control closer to the machines themselves. Unlike regular IoT systems, industrial edge platforms need to handle challenging demands, such as:

- Responding instantly in real time

- Supporting special industrial communication protocols

- Working even when offline or disconnected

- Connecting smoothly with SCADA, MES, and cloud-based AI systems

With edge capabilities in place, manufacturers gain:

– Faster local decisions

– Lower latency and higher availability

– Preprocessed, context-rich data ready for machine learning

– Lower costs by reducing cloud reliance and central infrastructure

FrameworX FactoryStudio: Flexible SCADA and IIoT at Any Scale

Tatsoft’s FrameworX FactoryStudio serves as the core platform powering both SCADA systems and edge deployments.

What sets it apart?

- It is built completely on .NET 8 to work well on different systems and deliver strong performance.

- It uses a Unified Namespace (UNS) that lets you access all data points, alarms, and calculated models easily.

- You can write custom logic using C#, Python 3.x, or VB.NET.

- It supports common industrial protocols like Modbus, OPC UA, MQTT, BACnet, and REST with built-in drivers.

- The system has open APIs and a clear, object-based design.

- Security is a priority, with encrypted communication, access controls based on user roles, and safe remote setup.

Whether on a desktop, in a Docker container, in a control room, or at the edge, FrameworX offers one reliable platform designed for both operational technology (OT) and information technology (IT).

EdgeConnect: Unmatched Power and Flexibility—Now at the Edge

EdgeConnect brings the capabilities of FrameworX to remote, embedded, and constrained environments, without compromising on functionality.

Deployable on:

- On Cisco routers

- On industrial devices running ARM/Linux

- On Windows or Linux computers

- Inside Docker containers

What EdgeConnect Can Do:

- Connects directly to PLCs using built-in drivers

- Lets you write custom scripts and change data locally

- Sends data based on events to MQTT or OPC UA systems

- Saves data during network outages and sends it later

- Runs analytics or AI tasks right at the edge

- Provides local dashboards using WebAssembly graphics

- Builds full device-level data models with UNS

And best of all—it’s affordable, with no extra charges for hidden features, and works smoothly with the main FrameworX SCADA system or your cloud setup.

SCADA at the Edge: Built-In, Not Bolted On

Unlike bolt-on edge agents or limited protocol gateways, EdgeConnect supports true SCADA functionality at the edge:

- Local data logging, alarming, and scripting

- Real-time event routing and decision logic

- Interactive dashboards or HMIs at remote facilities

- Synchronization with enterprise historians (Canary, Influx, OSIsoft PI)

- Preparation of clean, structured data for AI/ML tools in the cloud or on-prem

It’s not a stripped-down runtime—it’s an intelligent node that extends your architecture and increases reliability, scalability, and insight.

When to Use EdgeConnect vs FrameworX Unlimited

Tatsoft’s platform scales to your architecture:

| Use Case | Platform |

|---|---|

| Embedded edge control or protocol gateway | EdgeConnect |

| Plant-level SCADA + visualization | FrameworX FactoryStudio |

| Enterprise SCADA/IIoT + centralized UNS | FrameworX Unlimited |

All components are built on the same codebase, using the same designer and scripting environment—so scaling is easy, and there’s no need to retrain or rewrite.

Conclusion: A Smarter, More Secure Edge Starts Here

Tatsoft’s FrameworX and EdgeConnect help companies break free from outdated, disconnected systems. Whether you’re replacing old OPC servers, setting up a data pipeline ready for AI, or expanding SCADA to far-off sites, Tatsoft offers:

- An open, secure system that works in real time

- SCADA that runs at the edge—not just for monitoring

- Full access to all data models and namespaces

- Fast, reliable performance—even on small or low-power devices

- A strong base for future use with analytics, AI, and business systems

Call to Action

Learn more about Tatsoft’s Industrial Edge Platforms

Book a demo to see FrameworX and EdgeConnect in action

Explore the technical docs for deployment guides, scripting, and architecture examples