A major U.S. dairy producer set out to modernize its production operations by digitizing the flow of milk from incoming tankers through processing and final product output. With multiple facilities producing milk, cheese, and cream-based products, the company needed a unified, real-time tracking system capable of managing complex process data, ensuring full traceability, and integrating cleanly with existing MES, historian, and ERP systems.

At the core of the solution was Tatsoft FrameworX, selected as the foundational industrial platform to support real-time operations, standardized data models, and future Industry 4.0 initiatives. The system was designed and implemented by INS3, leveraging the FrameworX modern architecture to deliver a scalable, secure, and reusable milk tracking framework across plants.

The Challenge

Like many food and beverage manufacturers, the dairy producer faced growing operational and architectural challenges:

- Disjointed data flows between PLCs, historians, MES, and enterprise systems

- Manual tracking of milk batches, routing, and work orders

- Limited real-time visibility into tank levels, flow paths, and process performance

- Security concerns identified during a plant-wide IT audit

- A growing need for a standardized architecture to support genealogy, analytics, and digital transformation initiatives

Beyond solving immediate visibility issues, the organization wanted a solution that could be replicated across facilities, reducing engineering effort while maintaining consistent data structures and visualization standards.

As Andy, the lead developer on the project, explained during an internal presentation, the goal was not just to build an application, but to create a reusable and secure milk tracking framework that could scale with the business.

The Solution: A Milk Tracking System Built on FrameworX

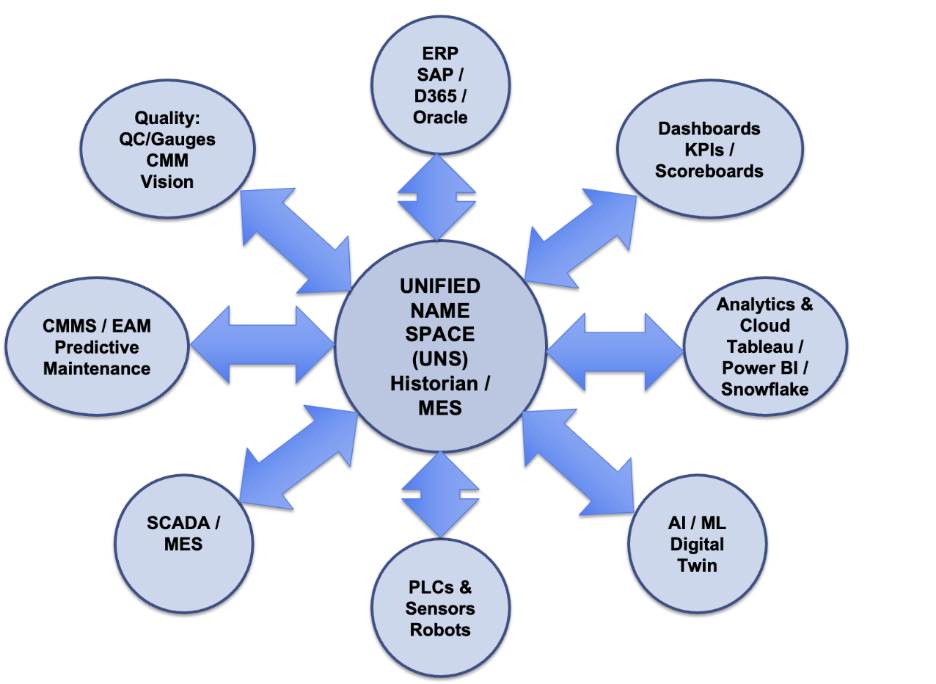

The solution was built using Tatsoft FrameworX as the core industrial platform, integrating seamlessly with MES, historians, and ERP systems through native OPC UA and SQL connectivity. The architecture followed Unified Namespace (UNS) principles, enabling clean contextualization of data across OT and IT environments.

Asset Model Architecture

FrameworX asset models were used to mirror plant operations, including intake, HTST pasteurization, loadout, cheese make processes, and silos. Hierarchical asset trees provided fast navigation, contextual binding, and a standardized structure that could be reused across multiple plants.

This approach allowed teams to maintain consistency while adapting to site-specific variations without redesigning applications from scratch.

Reference Tags and Object-Oriented Design

Each process area was modeled using reference tags and object-oriented classes within FrameworX. For example, pasteurization systems were defined once and instantiated across multiple lines and facilities.

With this structure:

- New equipment or lines could be added in minutes

- A single tag update could automatically generate new screens and data bindings

- Visualization and logic remained consistent across deployments

This object-oriented approach dramatically reduced engineering time while improving maintainability.

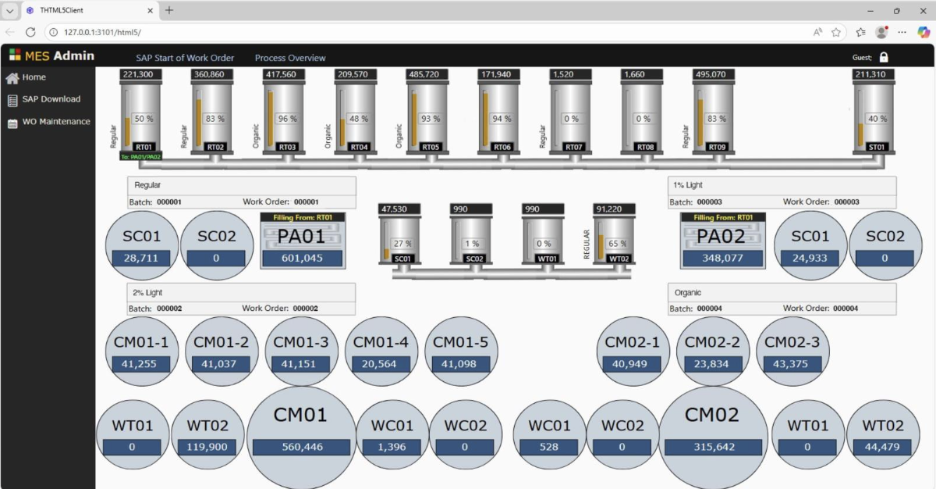

Work Order Synchronization and Process Flow Visibility

The milk tracking system was directly integrated with the MES layer, enabling operators to:

- Start and stop work orders

- View live milk totals by batch and destination

- Track routing to downstream processes such as cheese make or cream tanks

FrameworX maintained continuous visibility from intake to final output, ensuring accurate tracking of material flow and production performance in real time.

Real-Time Visualization and Dashboards

Unified dashboards combine PLC, MES, and historian data into a single operational view. Operators and supervisors accessed live information on:

- Tank levels and utilization

- Flow paths and routing status

- Production KPIs and throughput

Large overhead displays provide plant-wide visibility, improving situational awareness, and enabling faster decision-making.

Security and IT Alignment

Security was a critical requirement following a corporate audit. The implementation leveraged the FrameworX enterprise-ready architecture to align with IT standards, including:

- Secure OPC UA communication

- Network isolation between OT and IT systems

- Authenticated and encrypted connections

This ensured compliance with corporate security policies without compromising operational performance.

Results

The FrameworX-based milk tracking system delivered an immediate and measurable impact across operations.

Key Outcomes

- 900,000+ pounds of milk tracked daily with full process traceability

- Instant reporting on tank utilization, routing, and production rates

- Elimination of manual reconciliation between operations and quality teams

- Standardized logic and models enabling rapid deployment across additional sites

- Improved operator insight through intuitive, real-time dashboards

As Andy summarized:

“There’s no way I could have created this application in iFix or any other tool. With FrameworX, it’s structured, faster, and cleaner — even with complex logic behind the screens.”