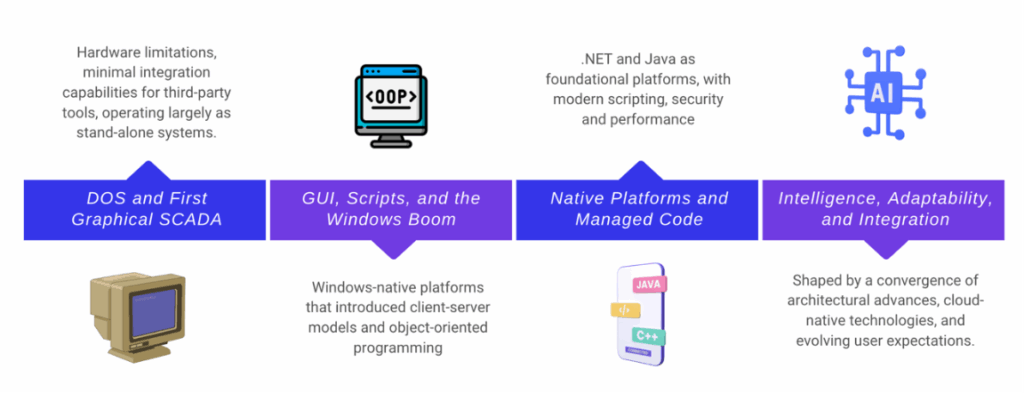

A Personal and Technical Journey Through Four Generations of SCADA HMI—and What Comes Next

Introduction: From Legacy to Modern SCADA

While SCADA technologies trace back to the 1960s often based on monolithic systems built on proprietary platforms or VMS, this article begins with the transformative shift of the 1980s. That shift coincides with the start of my own journey in the automation industry. It was the decade that saw the emergence of PC/PLC architectures, which began replacing older mini-computer-based systems.

My first hands-on experience came during a GM South America paint shop project in 1986, where DOS-based PCs communicated with Allen-Bradley PLC-2 controllers—a glimpse into the future that was already unfolding.

Today, when walking through control rooms, I often witness a troubling divide. Operators struggle with systems that crash during shift changes or maintenance updates, dig through dozens of screens for information that should be at their fingertips, and rely on separate spreadsheets because their SCADA systems can’t compute what they actually need.

Meanwhile, their competitors leverage platforms that aggregate data from any source, predict failures before they occur, and enable real-time collaboration from anywhere. As one plant manager with an old generation platform recently told me:

“We spend more time fighting our SCADA than running our process.”

After four decades in this industry, I’ve seen this story play out time and again. Companies clinging to familiar but outdated systems until a nimble competitor forces their hand. This journey from DOS to Windows to modern platforms reveals not only how technology has evolved, but also why sticking with “good enough” systems is often the riskiest decision of all.

Generation 1: DOS and the First Graphical SCADA

In the 1980s, the first generation of PC-based SCADA systems began to emerge. At the time, many industrial automation platforms were still built on mini-computers or VMS environments. Solutions like FactoryLink from USData, built atop IBM’s TopView operating environment, attempted to extend DOS with multitasking features and an open software bus. While architecturally elegant, these systems were often held back by hardware limitations.

Several similar efforts, such as Wizcon on IBM OS/2, Watcon, and various DOS extender-based platforms, gained attention briefly but were ultimately displaced. Other pioneering products, like Onspec, Genesis, TheFix, and Unisoft (my former company), focused on delivering practical results. These solutions were performance-optimized for the hardware of the era, often using C/C++, custom memory models, multitasking kernels, and direct access to the operating system and hardware.

Architecturally, these systems featured centralized tag definitions and custom-coded mappings to external devices. Most were based on closed, proprietary designs with minimal integration capabilities for third-party tools, operating largely as stand-alone systems.

Generation 2: GUI, Scripts, and the Windows Boom

The arrival of Microsoft Windows, particularly version 3.1 in 1992, brought a dramatic evolution to SCADA systems. Some companies responded by porting their DOS-based solutions or adding Windows-only display modules, while continuing to rely on legacy backends for tags and kernel-level functions. But the standout platforms were those designed entirely and natively for Windows – most notably Wonderware InTouch.

Over time, most major vendors followed suit, and by the mid-1990s, we began to see a clear “second generation” of SCADA systems: Windows-native platforms that introduced client-server models, ActiveX-based graphical interfaces, and scripting using VBScript, VBA, or proprietary languages. Device mapping and tag definition were still largely manual, but integration tools were beginning to mature.

Another key shift in the 1990s was the widespread adoption of object-oriented programming. When Microsoft Foundation Classes (MFC) 2.0 launched in 1994, it represented such a leap forward in tooling that I decided to completely rewrite our platform to leverage it. This effort led to the release of Unisoft for Windows in 1997—a second-generation product that became the foundation for several derivative solutions, including InduSoft and AVEVA Edge HMI.

Marc Taccolini the year Unisoft released, 1997

The lesson was clear: fully embracing the new technologies at that time —object-oriented design, updated programming languages, and new OS model—rather than clinging to legacy source code, created a robust foundation. Remarkably, derivatives of that platform remain in production today.

A similar pattern would emerge again in the next generation: some vendors fully redesigned their solutions for modern frameworks, while others added new UI layers over legacy internal structures (tags, scripts, kernels) that were never truly updated.

On the embedded side, Windows CE enabled the first wave of mobile HMI prototypes, such as our CE-based version for the Cassiopeia in the late 1990s. At the time, Linux lacked a standard graphical environment, and the effort required to maintain embedded panels with custom OS images made Windows CE an attractive option for low-cost systems. But Microsoft’s limited long-term investment in CE led many to migrate toward Linux and .NET Core-based platforms after the 2010s. From there, Gen 3 architectures introduced managed containers.

Casio A-11 with Windows CE

Generation 3: Native Platforms and Managed Code

The third generation of SCADA marked a pivotal leap forward with the widespread adoption of managed runtime platforms like Microsoft .NET and Java. The release of .NET 2.0 in 2005 and 4.5 in 2012 solidified the foundation for this era, offering performance, security, and scalability benefits that were previously difficult to achieve with legacy architectures. Today, .NET Framework 4.8 remains embedded in all modern Microsoft Windows distributions, and .NET 8 enabled Linux and a vast set of embedded and custom devices to deploy compatible runtimes, sharing the same application configuration.

Much like the DOS-to-Windows transition, a clean architecture rewrite was necessary, but for commercial, technical, or just practical reasons, not all established products were able to make the full transition. Gen 3 platforms that were natively built for .NET or Java quickly surpassed those attempting to retrofit modern features onto older codebases. Purpose-built solutions, such as Tatsoft’s FrameworX (.NET) and Inductive Automation’s Ignition (Java), demonstrated significant architectural and functional advantages over their predecessors.

Key innovations introduced in this generation included:

- Managed Runtime Environments: Full adoption of .NET or Java enabled memory safety, OS independence, garbage collection, and runtime stability. Security patches to the OS or runtime engine can be applied without breaking application compatibility.

- Sandboxed Design & Memory Isolation: Processes could operate independently, improving fault tolerance, stability, and security.

- Modern Scripting Support: Standard languages such as C#, VB.NET, and Python provided robust, multi-threaded scripting capabilities.

- Tight Database Integration: Direct SQL access with native drivers allowed efficient data interaction and storage.

- Thin-Client Architectures: Web-based and mobile client access became viable, with centralized deployment and management.

- OT/IT Convergence: Unified stacks began to blend HMI, MES, data services, and cloud integration into a single environment.

- Granular Security Models: Built-in user roles, encrypted channels, and auditing tools improved operational integrity.

- Reusable Engineering Components: Modular design patterns enhanced consistency and productivity across projects.

These features enabled a shift from fragile, monolithic systems to distributed solutions that were maintainable, performant, and scalable.

Thin Clients and Real-Time Dashboards – The .NET and Java Era

Legacy vs Modern: A Functional Snapshot

A side-by-side look at legacy versus modern SCADA platforms reveals the magnitude of transformation across usability, performance, and integration.

| Legacy SCADA | MODERN SCADA |

| Single-user dev, local-only tools | Multi-user collaboration with version control |

| Interpreted scripting (e.g., VBScript) | Managed languages (C#, VB.NET, python) |

| Manual memory management | Runtime safety and memory isolation |

| Pixel-based graphics (GDI/GDI+) | Resolution-independent WPF, XAML, SVG |

| Weak integration with enterprise systems | Native SQL and open REST/.NET APIs |

| Limited stability, OS/hardware dependent | Scalable, distributed, hardware abstraction |

Real-World Impact: From Days to Minutes

Some tangible performance and productivity improvements I witnessed firsthand during the Gen 2 → Gen 3 transition:

- Build Automation: Source compilation, testing, and package generation dropped from over a day to under an hour.

- System Setup: A water system production server built on a Gen 2 SCADA required a full-day manual deployment. The equivalent Gen 3 setup completed in under 10 minutes. Gains of 10x faster deployment and up to 100x more data points processing are common.

- Platform Migration: Rescaling a project to support a new display resolution or OS version dropped from days to minutes.

- Execution Speed: Real-time calculations previously handled by interpreted scripts saw a 15× performance gain after migrating to compiled managed code.

Generation 4 and Beyond: Intelligence, Adaptability, and Integration

Unlike previous SCADA platform generations, often defined by clear operating system shifts (from DOS to Windows, and from Windows to .NET), the fourth generation is shaped by a convergence of architectural advances, cloud-native technologies, and evolving user expectations. It reflects a broader digital transformation spanning engineering practices, IT/OT convergence, and AI-enhanced operations.

From a product perspective, while some components from the third generation can be retained, since platforms like .NET and Java remain relevant and continue to evolve, transformative architectural changes are essential. For example, Tatsoft FrameworX’s .NET-native design provided a strong foundation, but substantial architectural enhancements had to be included in its version 10 to fully enable Gen 4 capabilities.

Today’s fourth-generation platforms must support a new set of user and system-level requirements:

Engineering Lifecycle Integration and Collaboration

Gen 4 SCADA tools extend across the full engineering lifecycle, from design and validation to deployment and maintenance. Built-in version control, modular runtime management, and diagnostics ensure consistent project delivery and traceability.

Specific tools include:

- Real-time collaborative development with built-in version control and modular runtime management

- Hot-reload capabilities and change tracking for online/offline work

- Automatic environment-specific configuration (development, test, production) with correct network and database bindings

- Comprehensive diagnostics ensuring consistent project delivery and traceability

With those tools, engineering teams report 3-5x faster project delivery with reduction in deployment errors and manual configuration steps.

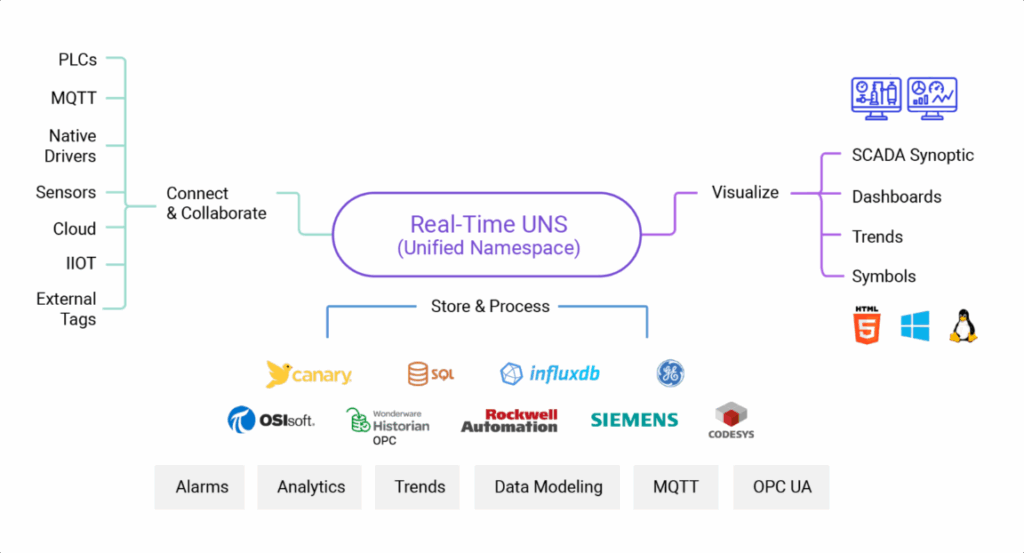

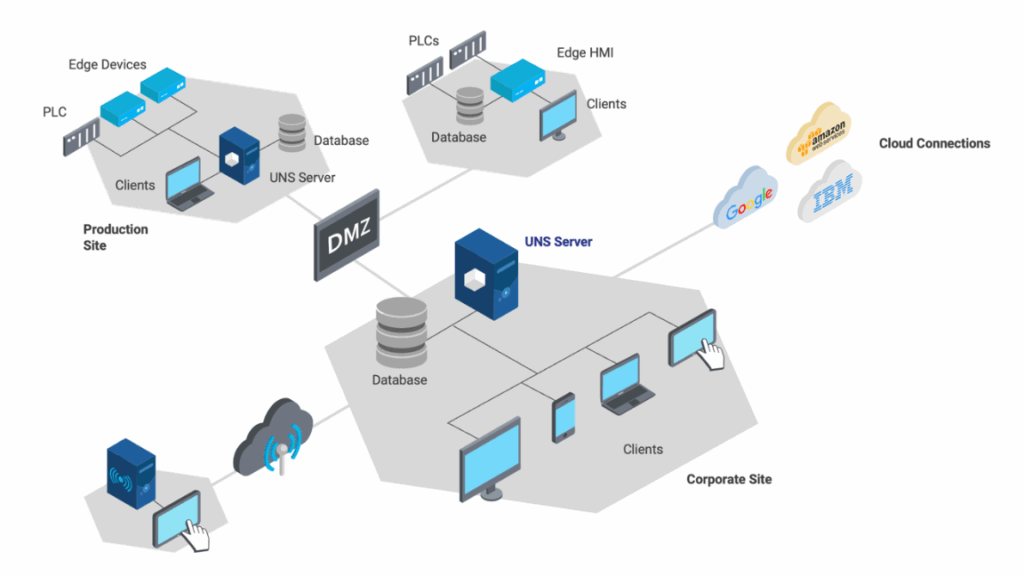

Contextual, Data-Driven Architecture

With support for Unified Namespace (UNS) and semantic modeling, Gen 4 platforms eliminate data silos and provide system-wide context. HMI components and automation logic can dynamically adapt to the addition or removal of field devices, no manual reprogramming required.

These capabilities include:

- Data-source agnostic integration enabling seamless connectivity to historians, databases, or data lakes regardless of vendor

- Hybrid network topologies combining local storage, enterprise servers, and cloud into unified, federated data fabric

- Semantic data modeling where systems understand context and relationships, not just raw values

- Dynamic system adaptation as devices are added or removed from the network

This has a direct impact on the business, as integration projects that previously required months now complete in weeks, with reduction in custom coding requirements.

The Intelligent Edge

Advanced edge devices now come with a series of tools that enable rapid onboarding of new data sources. These edge platforms can function independently or as part of a hybrid distributed system, as front-end UI, or in a data collector store-and-forward scenario. Development tools include:

- Autonomous edge operation with store-and-forward capabilities during network outages

- Built-in protocol support for MQTT, OPC UA, REST APIs as native capabilities

- Data Explorers for SQL databases, historians, OPC servers, and common PLCs (Rockwell, CODESYS)

- AI/ML inference engines running locally for real-time decision making

- Hybrid deployment models supporting front-end UI, data collection, or independent operation

New Visualization Technologies

With the advent of WebAssembly, web-based interfaces now deliver native-like performance for both desktop and mobile users. Factory-floor demands, such as sub-100 ms update response times, are met using modern web tech.

Other visualization tools include:

- Unified configuration tools building dashboards and traditional SCADA synoptics within single environment

- Responsive design engines ensuring optimal display across large screens and mobile devices

- Built-in accessibility features including light/dark modes, high-contrast support, and zoom scaling

- KPI-style views and interactive process screens delivered seamlessly through same interface

- Real-time collaboration enabling multiple engineers to work simultaneously

Human-Centric Intelligence: AI, AR, and Natural Interaction

Modern platforms now embed intelligence into both configuration and runtime layers:

- Conversational interfaces enable natural language interaction for commands and data queries.

- AR overlays enhance diagnostics and remote assistance.

- AI-assisted logic simplifies configuration, optimizes operator decisions, and feeds directly into predictive maintenance and analytics pipelines. These AI/ML tools convert raw data into actionable insights for quality, energy optimization, and predictive diagnostics.

Unified Toolset and Open Integration

Gone are the days of patching together a SCADA system from disparate parts (OPC servers, SQL connectors, separate brokers, scripting engines, optional modules and extensions). Gen 4 platforms are delivered as cohesive, full-stack toolset with built-in modules for UNS definition, alarms, scripting, historian, reports, and ERP/cloud sync.

Key integration features include:

- Open and unrestricted configuration, independent of production licenses.

- Native support for REST APIs, SQL, MQTT, and cloud platforms (as foundational components, not add-ons) and enabling third-party extensions.

- Built-in multi-protocol support across OT (Modbus, EtherNet/IP, etc.) and IT (SNMP, JSON/XML, etc.) domains.

- Built-in data servers with OPC UA, MQTT broker, and REST endpoints.

- Edge-to-Enterprise Scalability, with consistent runtime behavior across local devices, enterprise data hubs, cloud infrastructure and containerized deployments.

This consolidation breaks down silos between HMI, IIoT, MES, and IT systems, enabling a more agile, integrated, and future-ready automation ecosystem.

From Field Devices to the Cloud – Unified Infrastructure with Gen 4 SCADA

Conclusion: Generation 4 Meets Industry 4.0

The past 40 years have laid a strong foundation for what SCADA and HMI systems can achieve. But the technologies available today have pushed us beyond mere visualization or control – they enable the construction of intelligent, resilient, and adaptive platforms that break free from the limitations of legacy systems.

The convergence of Generation 4 SCADA with Industry 4.0 demands a fundamental shift in platform architecture, with systems that are open by design, built around event-driven architectures, semantic context, and edge-to-cloud scalability. This isn’t about retrofitting new features onto old frameworks, it’s about architecting for agility from the ground up.

The decision to modernize should not be made when existing systems begin to fail, but while they are still functioning. That’s when the return on investment is highest. By transitioning early, organizations gain the opportunity to redefine their workflows, enhance security, boost operational agility, and fully embrace digital transformation. And unlike previous platform transitions, this isn’t a matter of marginal improvement. The gains are exponential, not incremental.

Generation 4 SCADA systems align directly with the principles of Industry 4.0: modularity, interoperability, decentralization, and real-time data processing. But this alignment demands more than just adding IoT features or cloud connectors to old systems. It requires a fundamental architectural rethink. Companies that recognize this shift gain exponential advantages in speed, data richness, and adaptability. Meanwhile, those who delay may find themselves increasingly constrained, not only by technical limitations, but by missed opportunities for innovation and differentiation.

The window for strategic modernization is open now, but it won’t remain so indefinitely. The question is not whether your software platform can continue to run.

It’s whether it can lead!

Four Generations of SCADA: A Visual Summary of Technological Shifts

The Bottom Line

The question isn’t whether your SCADA can continue functioning, it’s whether it can enable your organization to lead in the digital era.

Every day you delay, competitors gain advantages through faster decision-making, lower costs, higher quality, and greater agility enabled by modern platforms.

Don’t wait for system failure. The optimal modernization time is while current systems function, enabling strategic rather than reactive transformation.

Take Action Today

Begin your Generation 4 journey:

- Schedule a platform demonstration tailored to your requirements

- Receive a complimentary SCADA architecture assessment

- Develop a customized modernization roadmap with ROI projections

- Access proven migration strategies from your industry peers

The future of manufacturing is intelligent, connected, and adaptive. Your SCADA platform should be too.

About the Author

Marc Taccolini has spent over 40 years implementing and evolving SCADA systems—from DOS-based controllers to modern IIoT platforms. He began his career in the 1980s as a field-startup engineer and, since the 1990s, has focused on platform software development. Marc has led hundreds of implementations spanning all major SCADA generations. He currently works at Tatsoft, assisting industrial organizations in navigating digital transformation through next-generation system architectures