Challenge

Modernize their SCADA system by replacing the legacy Opto 22 and Wonderware system to provide Operator Interface, Data Collection, and management of Alarms for refrigeration control system.

Solution

FrameworX makes it very simple to upgrade projects to new features and versions, while also keeping it simple to keep running the same software solution for many years. FrameworX offers real-time information and provides a complete set of modules in a unified and intuitive engineering user interface that creates a better understanding of the processes in the plant.

Results

“FrameworX is years ahead of the legacy systems still being sold today. Updating to newer versions is simple and reliable. We had none of the old-system update issues we’ve had with other packages in the past.”

— Phil Black, engineer at Tippmann Design Build

Wolverine Packing Company started in the Eastern Market of Detroit, and is now in its fourth generation of family ownership. What started in 1930 as a small lamb and veal packer has turned into a full-faceted protein company with multiple plants producing ground beef items, steak cutting, value-added products, and still to this day, fresh lamb and veal. Currently, they hold 38% share of the US market.

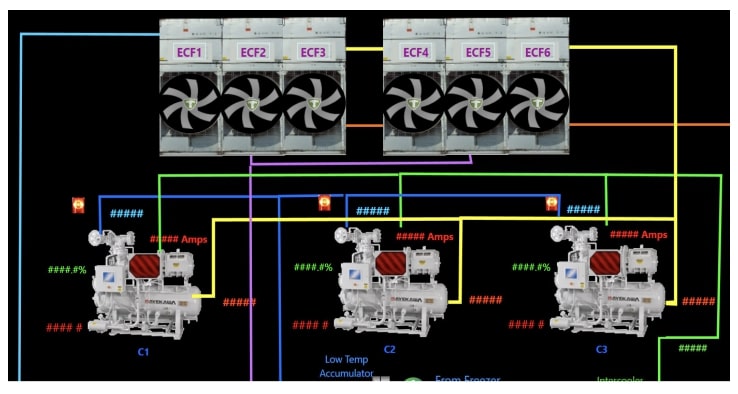

They first decided to implement FrameworX in their 300,000 square feet refrigerated warehouse in Detroit. There, they processed and packed portion-controlled ground beef items, high-end steak, and fresh lamb and veal. The purpose of the project was to replace legacy Opto 22 and Wonderware systems and provide operator interface, data collection, and management of alarms for the refrigeration control system.

FrameworX was chosen because it is a modern solution, ahead of its time, prepared for the future challenges the company might face.

The technical designers for the Tatsoft product started in real-time software application development around 1986. In 2009, they decided to take on a new challenge — the goal was to create a long-lasting platform with no use of any legacy code, neither intention to follow previous requirements. In fact, FrameworX was created with a new architecture and kernel, not tied to or looking to the past, but leveraging our current technological environment.

The project used six FrameworX Smart (Thin) Clients and 1500 external I/O points. The other system feature that helped Wolverine manage their processes was the ability of FrameworX to run in a virtual machine with Windows 10 on the data center server.

Updating to newer versions was made simple with FrameworX, reducing engineering time, mainly because every project is stored in its own embedded SQL-database file. Newer versions may have new columns or even tables in the database. But even so, FrameworX is much more efficient and reliable when compared to legacy systems which force you into reconfigured flat files followed by some sort of global search and replace procedure.

Other standard modules FrameworX offers that can be used in the refrigeration industry include real-time tags and assets database, user templates, alarms and events, historian, XML, CSV, XPS and PDF reports, built-in embedded SQL database engine and web server, C#, VB.NET, and Java scripting languages, scheduling, OPC server and client, embedded communication protocols, and graphical designer, with native runtimes for .NET, Web, iOS, Android, Windows Compact Framework (Windows CE), Linux, including Raspberry Pi (rPi).

“FrameworX has helped us reduce energy costs, lower the use of materials, increase the uptime, as well as gain traceability and quality control. Expected benefits will be derived as the more you know about your process, the more you understand it, leading you to develop new fabrication processes, or new products and technologies that ultimately are responsible for the long-term growth of the company.”

— Phil Black, engineer at Tippmann Design Build