Challenge

The Refinery had outdated legacy software and needed to update the interface to each of their systems with the latest proven design, better stability and reliability, that could provide high-quality graphics, high-speed data analytics and allow the operators, technicians and engineers to maintain a high level of confidence with the system retrofit.

Solution

The company chose FrameworX because it could provide high speed controller data for fast and efficient analysis. The software was also extremely efficient and engineering time was reduced.

Results

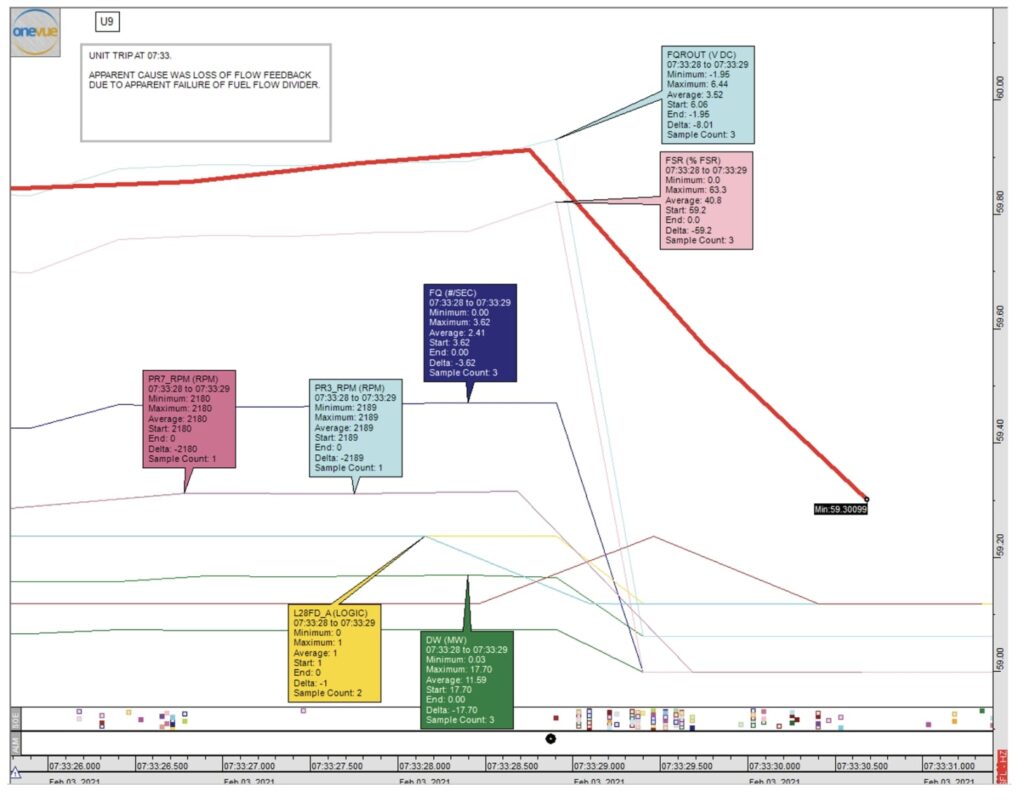

The updated software allowed the company to analyze the Control Unit quickly and efficiently, leading to quicker resolution to issues by presenting real-time data, cold hard facts, and no longer hearsay to management so they can focus their attention to the production and overall efficiency of the plant’s operation.

- Real-time alarms helped the unit to continue operation safely, where otherwise the unit unloading, runback or to even shutdown was prevented.

- When comparing the upgrade cost and the amount of engineering hours required, compared to other units, the cost reduction by using FrameworX exceeded $40,000.

- With the ability to perform data analysis on every point in the control system, the company found problems they did not even know existed. This increased efficiency and availability due to resolving issues without shutting down, and to preplan for immediate outage support.

“When compared to their original software, the customer was overheard saying many times, ‘Man, this is like magic!’.”

Ron Walker, President at Control System Technologies, was the system integrator that worked on the project.

FrameworX came through

Limetree Bay Refinery is a world-class refinery, terminal, and logistics hub that will help transition the maritime fuel sector toward new international standards. Further, it is well-situated to process the growing supply of Latin American sour crudes to fulfill consumer demand in growing end markets in the Caribbean, Central and South America, and the U.S. East Coast.

Besides the need to update their outdated legacy software, the facility also needed new technology to expand their goals. With the right tools, like FrameworX, they knew they could support the transition to new international maritime standards, while also providing needed economic development in the U.S.V.I. This would create more than 1,500 local jobs during construction and 400 full-time jobs beyond 2020.

New data allowed for better, more efficient decisions

The project focused on restarting certain refining operations in the more modern East Refinery, which includes Crude Units, a Vacuum Unit, Coker, Platformers, Hydrotreaters, FCC, an Alkylation Complex, a ULSG unit, and a Sulfolane Complex.

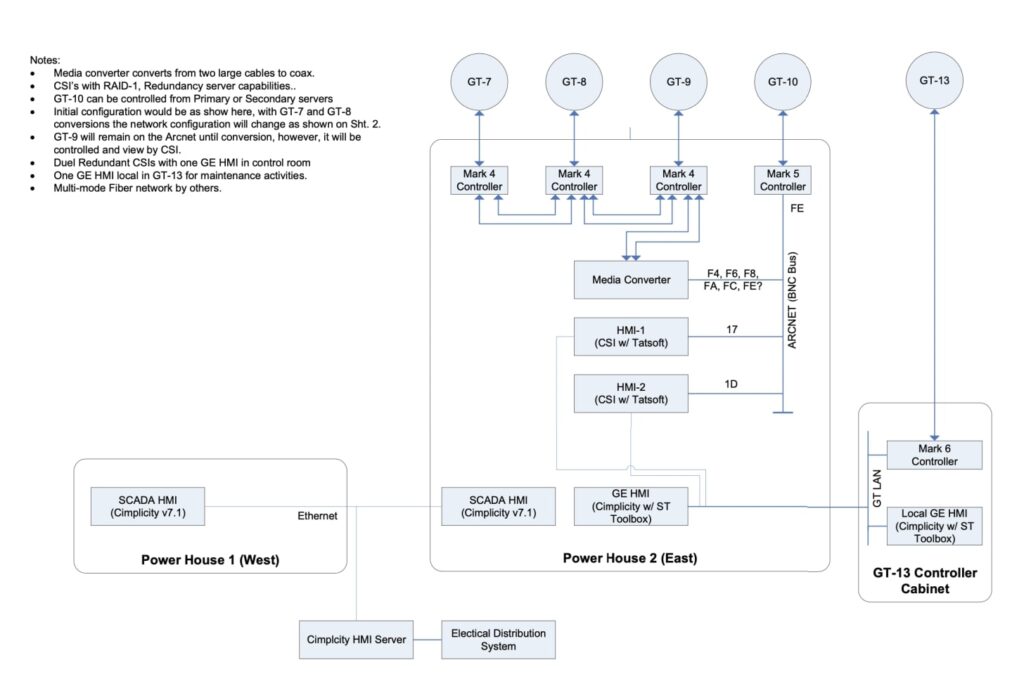

To do that, Limetree needed data — FrameworX allowed them to interface with the Control System Technologies CSI Controller and OPC, capturing data from digital pressure and temperature switches, LVDTs, RVDTs, TCs, RTDs, speed probes, vibration probes, isolation valves, control valves, diesel engines, MCCs, and 13.8 kV breakers.

Control System Technologies was the chosen integrator for this system and tailored their design for a Generator Load Control and Auto ISOCH Selection system, integrating it with the initial project. Legacy technology couldn’t meet their modern needs… Control System Technologies with Tatsoft did!

With real-time data available, the updated system provided powerful analysis capabilities to operators, technicians, and engineers. The operator interface was simplified, trending improved, and data analytics delivered key insights to plant operations.

OneVue data analytics software, combined with the Legacy Data Recorder (LDR) high-speed data collector, made it possible to plot thousands of trends on the same chart simultaneously — the foundation for understanding conditions that required correction. High-resolution, time-synchronized visibility into system behavior allowed engineers to see precisely what was happening in the unit or plant.

User Nodes

The system began with four concurrent users. When fully implemented, it will support up to 25 simultaneous clients with fault-tolerant redundant servers, maximizing uptime and guaranteeing access when needed.

Tags / Communication Points

The system includes over 10,000 communication points from multiple controllers and is licensed for up to 15,000 real-world I/O.

Engineering Time

Initial CSI system design took approximately 10 weeks.

A later request from the customer for a high-efficiency grayscale color scheme took an additional 6 weeks to implement.