CHALLENGE

Before the introduction of the new Signal Testing System, testing and commissioning railway signal systems were labor-intensive and error-prone. Several signal personnel were required to be present in the field during the cutover phase to manipulate signal inputs and outputs, making it a time-consuming and costly process. Testing engineers often had limited visibility of the overall control system, leading to potential errors and delays in the cutover process.

SOLUTION

FrameworX by Tatsoft was selected as the platform to build the Signal Testing System due to its flexible, real-time capabilities. The system was designed to allow remote manipulation of signal systems from a centrally located mobile command center (Cutover Trailer), eliminating the need for on-site personnel at multiple field locations during signal system testing. The two main components of the system are:

- Wayside System Simulator (WSS): This device simulates real-world signal behaviors such as the movement of trains, switch operations, and signal responses. It collects input from the field and sends it to the mobile command center.

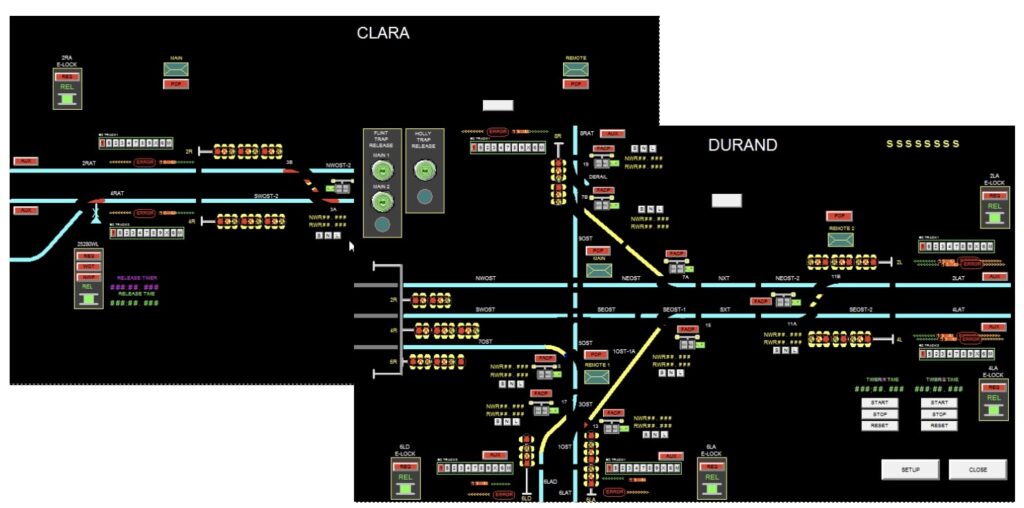

- Mobile Command Center (Cutover Trailer): Equipped with an HMI (Human-Machine Interface) powered by FrameworX, this centralized unit allows engineers to remotely control and test signals without requiring personnel at the field location.

RESULTS

The Signal Testing System, built using FrameworX by Tatsoft, has revolutionized how Herzog tests and commissions railway signal systems. By leveraging remote manipulation and centralized control, the system has:

- Reduced field personnel requirements by over 60%.

- Increased the accuracy of tests and reduced human error.

- Minimized testing time by up to 70% in some cases.

- Reduced costs related to overtime, lodging, and other logistical overhead. • Improved safety by limiting the exposure of personnel to the field environment.

Key Features of the Signal Testing System

Safety and Accuracy:

With most field personnel eliminated from the testing process, the chances of human error were significantly reduced. Engineers could focus on the entire control point system, minimizing the risk of errors. The testing was conducted in a controlled environment, which allowed more careful and comprehensive pre-testing and commissioning.

Quality Assurance:

The system allowed the testing engineer to simulate various scenarios that are often difficult to replicate in live environments. This led to a higher-quality product with fewer errors.

Cost Control:

By reducing the need for field personnel during pre-testing and in-service testing, costs related to manpower, overtime, lodging, and overhead were reduced significantly. The in-service testing time was cut down by 70% in many cases, further contributing to cost savings.

Remote Control and Monitoring:

Using the FrameworX connectivity features, the system enabled real-time communication between the WSS units in the field and the mobile command center. Engineers could monitor and control the signal system’s inputs and outputs via Ethernet, ensuring seamless testing from remote locations.