Mesa Associates Incorporated is a full-service engineering, procurement and construction management firm specializing in power, defense, aerospace, industrial, commercial and municipal entities. Mesa offers power delivery systems including electrical high-voltage, substations, switchyard, transmission line, and distribution design. Mesa also provides SCADA, PLC, and systems integration services to include server setup with standard and virtual systems. The company’s headquarters is located in Madison, Alabama with satellite offices located across the United States. Their systems integration department along with their machine build group is located in Knoxville, Tennessee with a panel build facility located in Greeneville, Tennessee.

Mesa’s System Integration team was hired by a boiler manufacturing facility located in middle Tennessee to engineer a new boiler test station solution for the company. The project scope required the system to retrieve test parameters from a remote SAP PI system located in Ohio. Using the unit’s serial number, the system queries the SAP database for the specific test parameters needed. The scope also requires the production test stands to be separate from the SAP PI interface to maintain network security. The test stand interfaces with a high-accuracy PLC system monitoring flow meters and flow switches supplying gas flow to the main test boiler. Flow rates for the system are in the 3 to 5 million BTU ranges and have to maintain an accuracy of 1% of reading. Communications to the PLC is through Modbus TCP/IP.

The project scope also required the new system to be easy to install, with the recovery files consisting of two or fewer files to store the project. The solution also had to be easily expandable with a way to monitor the connection to the SAP PI web services.

Mesa viewed several SCADA packages offering possible solutions utilizing web services interfaces. Each solution required a main server system complete with either ThinManager or an ERP system in order to provide a web services access point. This approach drove the project cost out of the budget range Mesa was given to complete the project.

“Most standard SCADA packages we reviewed had a subset of Visual Studio capabilities or a trimmed-down version of VBA. FrameworX from Tatsoft was finally selected due to the full Visual Studio-compliant features and low I/O point count cost,” according to Project Manager Greg Dixon.

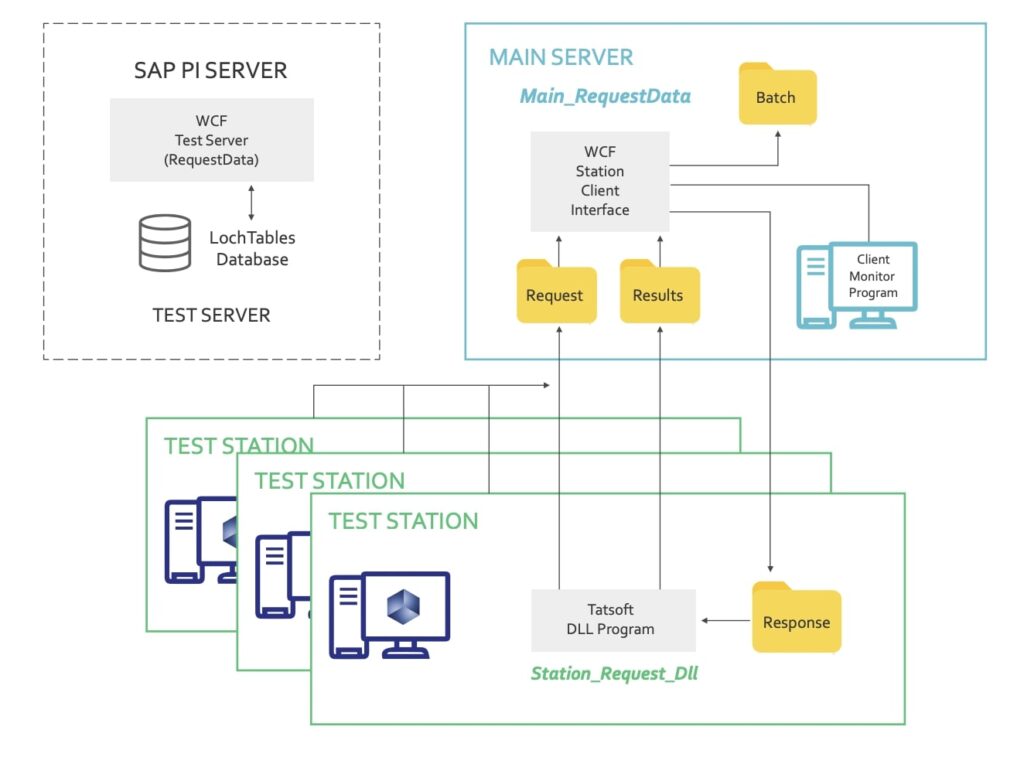

The project consists of a main web server with dedicated internet access outside of the plant. This approach allows multiple access to the web services without allowing internet access to the plant floor. The web server has a web services interface to the SAP PI system. Requests for recipe queries are made through a simple directory-change event monitored by the web-service program at each test stand. This makes a secure link exchange between the web server program and each test stand. Data is exchanged in a structured text format.

Received data from the web services is structured to take advantage of FrameworX’s ability to mimic a DLL property’s structure. This allows only one line of code in FrameworX to transfer the recipe data for up to 24 individual test parameters and recipes. This helps move the testing outside of FrameworX and allows robust compliance testing within the Visual Studio environment. Since FrameworX is a fully .NET-compliant platform, event procedures are easily picked up from the DLL.

As shown below, each station contains the Tatsoft SCADA system along with the embedded DLL file created in Visual Studio. Since FrameworX is also fully Visual Studio-compliant, this made creating the DLL interface simple and easy. Events were created triggering functions within FrameworX, allowing real-time updates to the operator’s screen. Communication is done by simple file sensing using Windows File API functions available in Visual Studio. Requests are made to the Windows Communication Foundation (WCF) Station Client Interface program outlined above. Response files from the WCF interface are sent back to the test station within 3 ms. This allows for a simple file-protocol interface and creates a secure environment for the plant network since only text files are used to send the data.

In addition, no special software or requirements for the system are needed other than simple file sharing. This was easily accomplished through shared drives. Greg Dixon, who is also a certified CAP integrator with Mesa Associates, created the design and configured the system. He also programmed the PLC interface as well as the WCF client interface program. The system was designed to accommodate multiple stations and uses the file interface as a storage buffer when multiple stations request data at the same time.

The system is tied to a Cymon PLC unit via a TCP/IP link to the processor. This type of system places a low demand on the PLC unit, requiring only scaling and digital feedback of sensors. The interface between the PLC and FrameworX requires only 82 tags, well within the minimal requirements for a low-cost interface unit.

FrameworX’s unique ability to structure DLL properties into a structured tag allowed Mesa to quickly create a unique interface where much of the heavy lifting is accomplished in the DLL code rather than the FrameworX programming system. This allows Mesa to develop the web services interface using established programming standards to test the system outside of FrameworX.