MES Software

for Real-Time Manufacturing Operations

Open and Flexible Software for MES and Manufacturing Intelligence

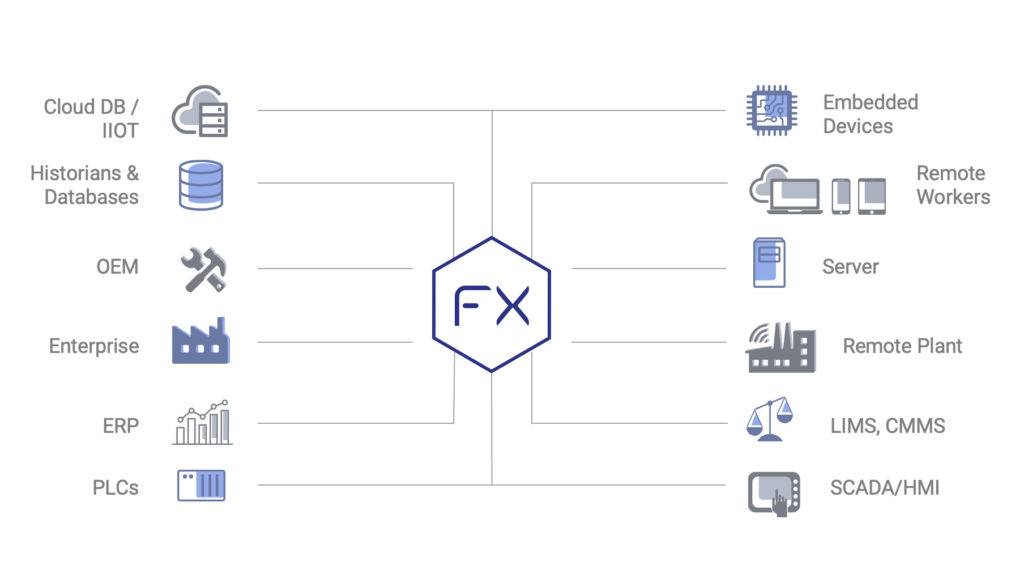

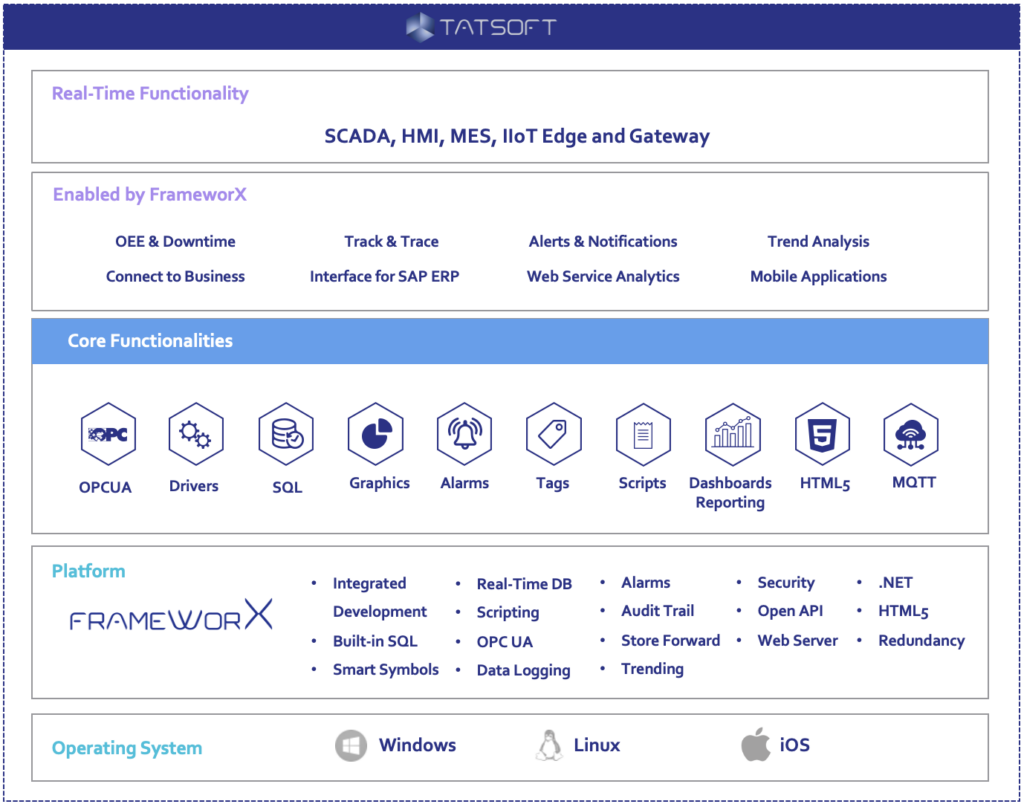

We help Manufacturing companies gain visibility and achieve operational improvements with the use of our flexible software platform. Tatsoft’s FrameworX can help with performance monitoring, downtime tracking, track and trace, shop floor scheduling, batch tracking and more. We offer an open and layered technology that can fit your technology landscape and give you scalable capabilities to connect to any data source and provide visual applications to optimize your operations.

Built-In MES Functionality

Complete

Everything you need in one installation, built-in real-time drivers, SQL, alarms and alerts, MQTT and OPC UA.

Unlimited Licensing

Connections, Clients, Developers. Connect to anything and create MES, SCADA Dashboards & more.

Security & Redundancy

Mission-critical security at the core level, collect real-time data, integrate to enterprise systems.

Alerts and Notifications

Alerts on production events, logging, scripts. Notification by email, SMS. Acknowledge, display and act.

OT meets IT Architecture

Flexible architecture and configurations to optimize your IT standards, and fit existing landscape.

Integrate to Any Cloud

Microsoft Azure, AWS or any cloud platform, we are Open and Secure.

Connected Data Hub

Edge computing, store/forward to SQL, Data Historian or IIoT Cloud.

Integrate to Anything IT

ERP, MES, Quality, Maintenance, Documents, SQL or NoSQL Databases.

Scripts to Enable Analytics

Powerful script engine at the edge or in the Cloud, C#, VB.NET, Python. Script on Production Event.

It’s not uncommon to hear, “This is like magic,” during Tatsoft training sessions when customers are upgrading from legacy solutions. Tasks such as design or troubleshooting can be completed in just one-tenth of the time with Tatsoft compared to traditional legacy systems.

- Control System Technologies

One of the main reasons we decided to work with Tatsoft is they have decades of experience in developing software products and understand the need to have a flexible, reliable platform on which to build applications that will last a long time.

- Renifer Systems

I can’t tell you how many people have come through this building. International groups are very interested. We like showing it off. The system is a big change from what we had; everybody appreciates it.

- Cargill Feed Safety Research Center

The other packages we looked at were either extremely long in the tooth, could only communicate with a single PLC, or were lacking in data collection capabilities (…) FrameworX also provides the tools for us to make complex animations that were essential for us to separate ourselves from the competition.

- Rite Irrigation LLC

Other key factors leading to our decision to use FrameworX were the wide range of options for displaying graphics, built-in .NET scripting for special requirements, communication flexibility, and competitive pricing.

- Water and Wastewater Industries

Integrate and Connect to Manufacturing Data

The FrameworX platform is built to connect and the software includes a complete set of interfaces to real-time data as well as any database data. FrameworX comes with many PLC, CNC and DCS drivers and can be an OPC UA client or server. We also have an open API and have developed over 200 drivers.

Powerful Unified Development for Manufacturing Execution System

A complete platform provides all your development tools in one place. FrameworX takes care of versions and version control automatically. Manage and track configuration changes to audit log. Copy/paste any config to Excel. Tags, Datasets, Alarms, Devices are all object as type with Intellisense.

Create Visibility into your Manufacturing Operations

A complete software solution that can help you unlock the full performance potential of your manufacturing operations by giving you a real-time understanding of what is happening, right now, on your plant floor. Actionable information, real-time on any device.

FrameworX for MES

Alarm and Notification

Multi-threaded alerts, log to SQL, scripts subscribe to events. Send emails, texts, or custom actions.

Unlimited Licensing

Connections, Clients, Developers. Connect to anything and create MES, SCADA Dashboards & more

Secure

Mission-critical security at the core level, collect real-time data, integrate to enterprise systems.

Built-In SQL

Embedded SQL engine included or integrate to any SQL.

OT meets IT Architecture

Flexible architecture and configurations to optimize your IT standards, and fit existing landscape.

Data Logging

Log time-series data to any SQL database analytics, store and forward included and easy to configure.

Scalable and Modular

Our architecture allows you to start small and then scale and distribute the platform, where you need it.

Dashboard Builder

Build dashboards and connect to data as part of your HMI.

Audit Trail Anything

Log events; you can choose which events to securely log to an encrypted SQL database

Integrate to any Historian

Seamlessly integrate to any process historian including OSISoft PI, Canary Labs, GE, Wonderware and more.

Scripting

Code behind and expressions using VB.NET, C#, HTML5/ Javascript and Python.

Integrate to Any Cloud

Microsoft Azure, AWS or any cloud platform, we are Open and Secure.

Connected Data Hub

Edge computing, store/forward to SQL, Data Historian or IIoT Cloud.

Integrate to Anything IT

ERP, MES, Quality, Maintenance, Documents, SQL or NoSQL Databases.

Redundancy

Server, device communications easily configured for redundancy.

FAQ

MES software (Manufacturing Execution System) connects the plant floor with business systems to track, control, and optimize production in real time. It provides visibility into performance, quality, and resource utilization—helping manufacturers reduce downtime, improve efficiency, and ensure product consistency. Tatsoft’s FrameworX MES software integrates seamlessly with SCADA, HMI, and IIoT layers, providing a unified data model across the enterprise.

Tatsoft FrameworX uses real-time data acquisition, analytics, and event management to identify performance bottlenecks and prevent downtime. Its MES software modules track production KPIs, OEE, and quality metrics, helping teams respond instantly to process deviations. By connecting automation systems with visualization and reporting tools, FrameworX provides actionable insights that drive continuous improvement.

FrameworX delivers a full suite of MES software capabilities, including production tracking, quality management, genealogy, work order execution, and downtime analysis. It also offers integrated dashboards, alarm management, and reporting for complete operational visibility. With native support for Python scripting and .NET logic, users can customize workflows and analytics for any manufacturing environment.

Tatsoft FrameworX integrates natively with over 100 connectors, including controllers, sensors, and databases using standard protocols such as OPC UA, MQTT, Modbus, and SQL. Its open architecture allows connection to ERP, historians, and IoT systems without custom middleware. This makes it ideal for building a connected MES environment that spans from the edge to the enterprise.

Tatsoft’s MES software is used across discrete, batch, and continuous manufacturing environments. It is ideal for industries such as food & beverage, energy, life sciences, water treatment, automotive, and OEM machinery. Because of its flexible architecture and unlimited scalability, FrameworX supports both single-plant and multi-site enterprise deployments.

Tatsoft provides flexible licensing models for its MES software, including perpetual, subscription, and OEM-embedded options. You can check out our pricing here.

Tatsoft FrameworX supports both Python and .NET (C# and VB.NET) scripting environments, providing flexibility for automation, data manipulation, and advanced customization. Engineers can extend MES workflows, integrate APIs, and build advanced analytics directly within the platform—eliminating the need for external tools.

FrameworX includes a powerful real-time alarm and event management system integrated directly into the platform. Users can configure alerts for production events, process deviations, or quality issues. Audit trails record all user actions and data changes, supporting traceability and compliance in regulated industries.

Yes. Tatsoft’s MES software allows seamless integration of analytics, AI, and machine learning models. Users can connect to Python-based AI libraries, external APIs, or cloud analytics platforms. This enables predictive maintenance, advanced quality analysis, and optimization of production processes—all within the FrameworX environment.

Yes, we have reliable and easily configurable redundancy for seamless failover. Realtime tags, devices, alarms, historical data, scripts, clients, and all modules were designed to meet redundancy and hot-swapping requirements.

Tatsoft FrameworX includes a unified development environment (Studio) for creating, deploying, and managing MES applications. Engineers can design screens, configure tags, manage databases, and implement scripts—all from a single workspace. Built-in versioning, debugging, and deployment tools streamline development and reduce engineering time.

Migrating to Tatsoft FrameworX MES software is simplified through import tools and flexible data mapping. Tatsoft supports integration with existing PLCs, SCADA, and databases, allowing gradual transitions from legacy systems. The engineering team provides migration assistance to ensure minimal downtime and faster modernization.