Human Machine Interface (HMI) Software

Modern Human Machine Interface Software for Industrial Automation

Why Choose Tatsoft for HMI?

Tatsoft’s MachineHMI is an open and flexible software platform for developing traditional, high performance and modern HMIs for your operators. Create fast, robust and secure displays with our human machine interface software, with real-time graphics, trending, alarms and alerts. Ready for Industry 4.0 so you can answer the need for actionable information and actionable intelligence.

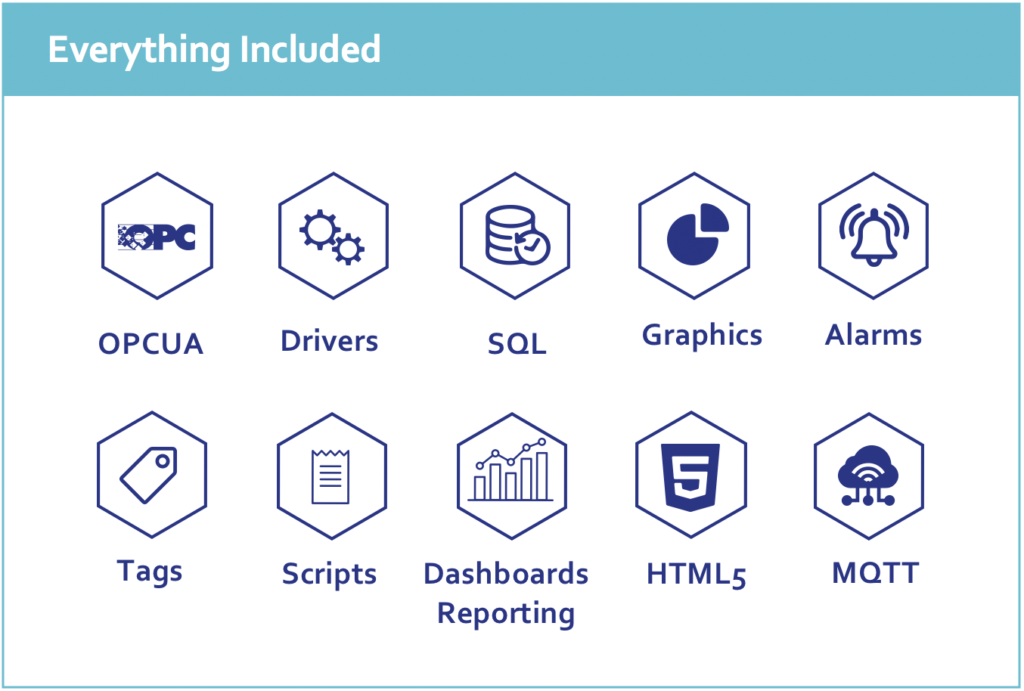

Key HMI Capabilities Built-In

Complete

Everything you need in one install, built-in drivers, SQL, redundancy, reporting, and more.

Create Fast and Powerful

Reusable symbols and components, projects stored in one secure file, built-in versioning.

Security & Redundancy

Mission-critical HMIs, Security at the core level.

Affordable

MachineHMI is sized to your application, includes drivers, MQTT, audit trail and more.

.NET and Web

.NET means reliability and intrinsically safe. Web means easy to deploy.

Integrate to Anything IT

ERP, MES, Quality, Maintenance, Documents, Databases.

Connected Data Hub

Edge computing, store/forward to SQL, Data Historian or IIoT.

You Choose Hardware

MachineHMI works on any flavor of Windows as well as Linux and iOS (iPhone, iPad).

Powerful Scripting

C#, VB.NET, Python, Code Editor, Create Tasks, .NET Classes.

It’s not uncommon to hear, “This is like magic,” during Tatsoft training sessions when customers are upgrading from legacy solutions. Tasks such as design or troubleshooting can be completed in just one-tenth of the time with Tatsoft compared to traditional legacy systems.

- Control System Technologies

One of the main reasons we decided to work with Tatsoft is they have decades of experience in developing software products and understand the need to have a flexible, reliable platform on which to build applications that will last a long time.

- Renifer Systems

I can’t tell you how many people have come through this building. International groups are very interested. We like showing it off. The system is a big change from what we had; everybody appreciates it.

- Cargill Feed Safety Research Center

The other packages we looked at were either extremely long in the tooth, could only communicate with a single PLC, or were lacking in data collection capabilities (…) FrameworX also provides the tools for us to make complex animations that were essential for us to separate ourselves from the competition.

- Rite Irrigation LLC

Other key factors leading to our decision to use FrameworX were the wide range of options for displaying graphics, built-in .NET scripting for special requirements, communication flexibility, and competitive pricing.

- Water and Wastewater Industries

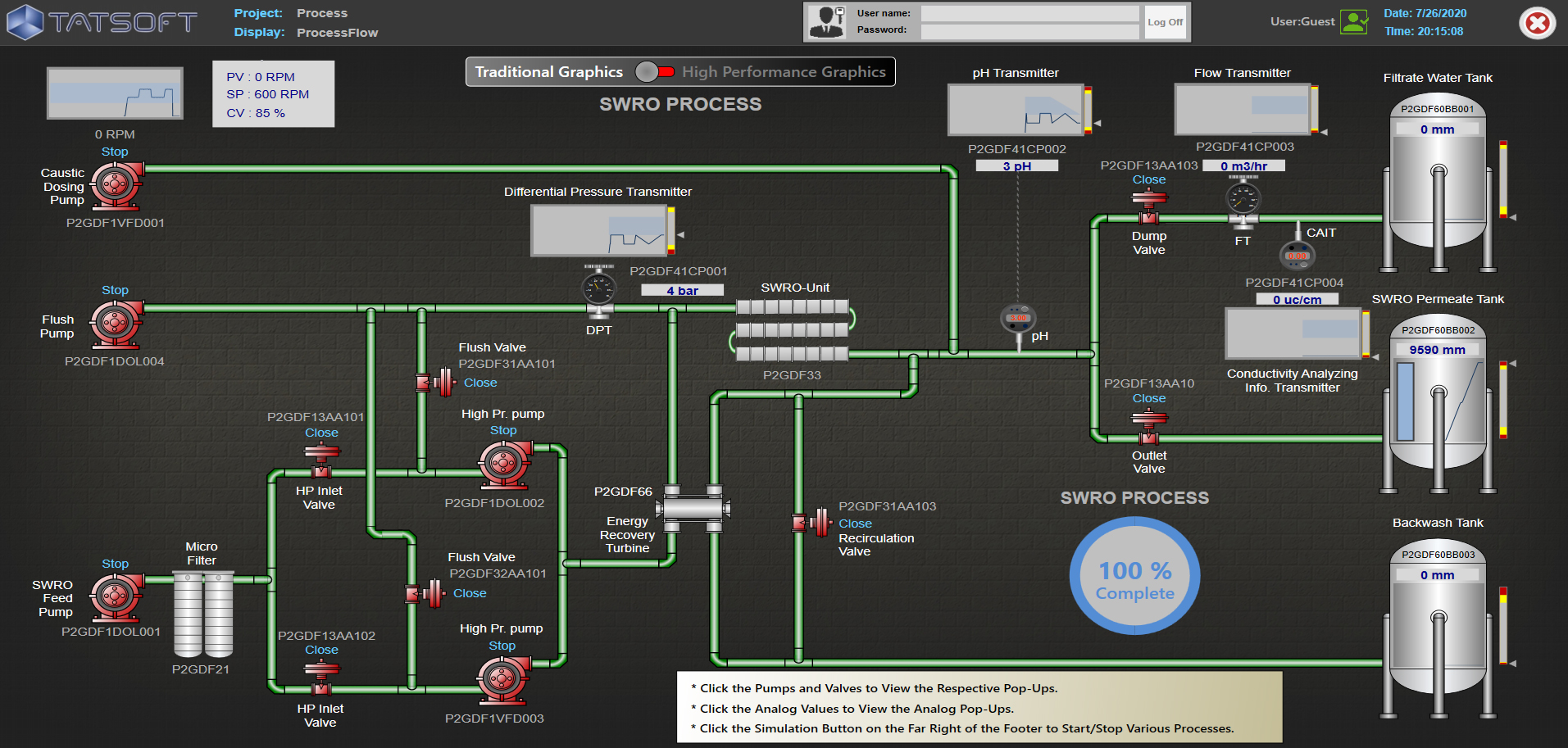

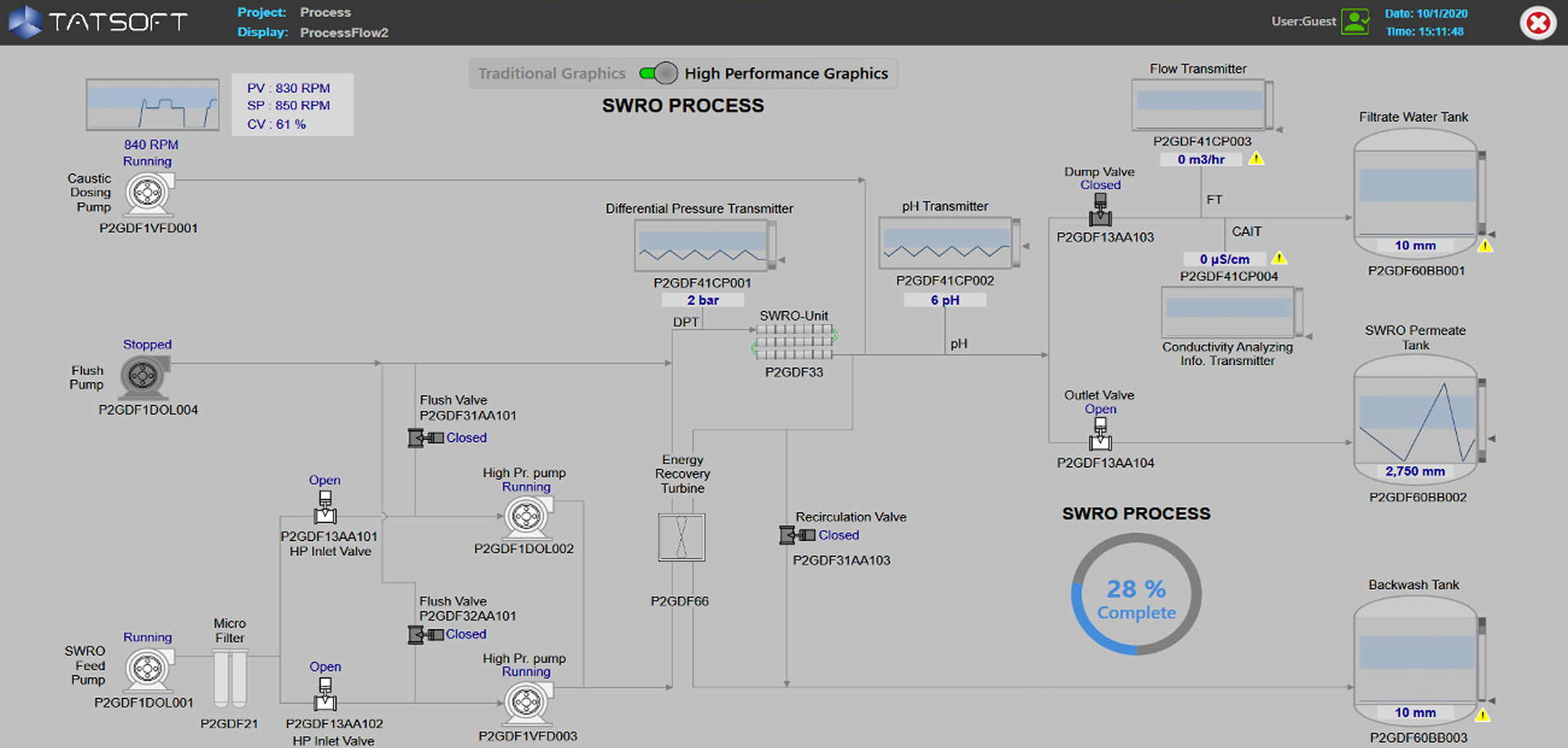

Grab slider and move left/right to see more

Graphic Designer to build Dynamic HMIs

Our human machine interface software includes a complete set of tools for creating rich interactive displays for analyzing your real-time and historical data. We include a full set of symbols and components so you can easily build HMI graphics, charts, trends and alarm screens. Build or add your own symbols, we give you limitless possibilities. Dynamic Symbols are powerful ways to decrease your development time with runtime template binding and central management.

– Rich vector drawing tool or use symbols and components or import .NET or HTML5 controls

– Comes with a Dashboard designer to simplify creation of powerful data visualizations

– Code behind and expressions provide flexible customization on animations and client-side events

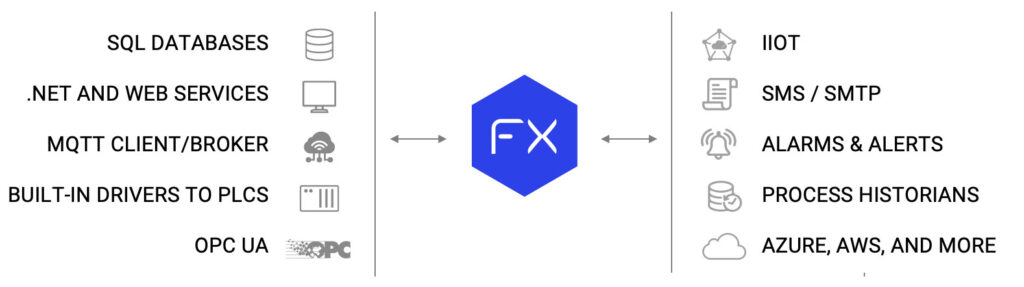

HMI Software that connects to PLCs, DCS, OPC, MQTT

Included with MachineHMI at no additional cost are many protocols, like; Rockwell, Modbus, Siemens, Omron, OPC UA, MQTT,SNMP, BacNet, and many more. We also have a driver toolkit that you can use to develop drivers or let our team do the work we’ve developed.

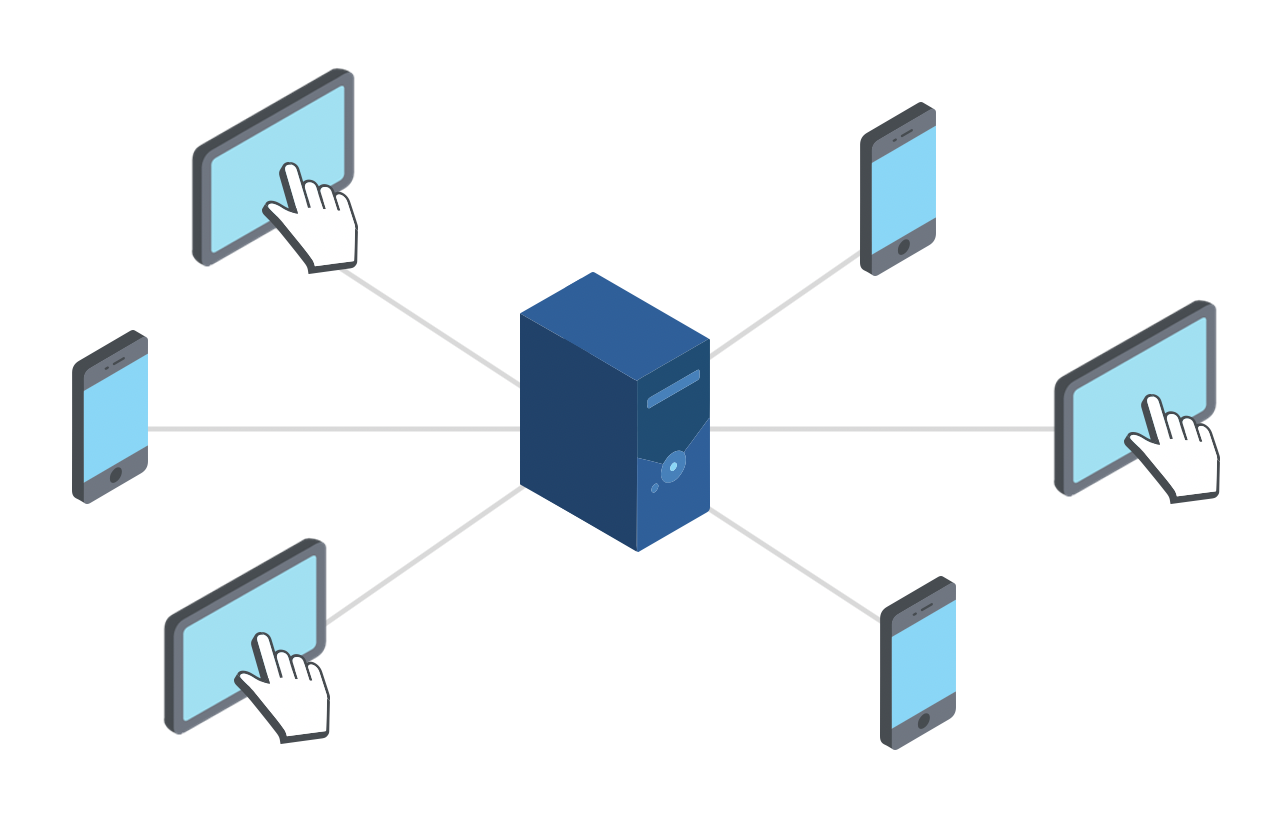

Multi-Platform, Multi-Touch, Multi-Monitor HMIs

MachineHMI runs in many environments choose an industrial HMI or lower cost device. We support any version of Windows, including CE, as well as Linux, Raspberry Pi, and Apple iOS. From edge to large format displays. Simple to configure Multi-Monitor support.

HMI Data Logging and Trending

Log data to the built-in SQL database or external databases, like Microsoft SQL Server, Azure or Oracle. Advanced visualization and annotation features. Log tags, alarms, events. Store and Forward to a remote database or process historian. Advanced data grid and trending tool for analyzing historical data.

- Plot logged data with any SQL data on the same chart

- Trend charts are configurable or fully customizable

- Vertical and XY charts with all properties available to scripts

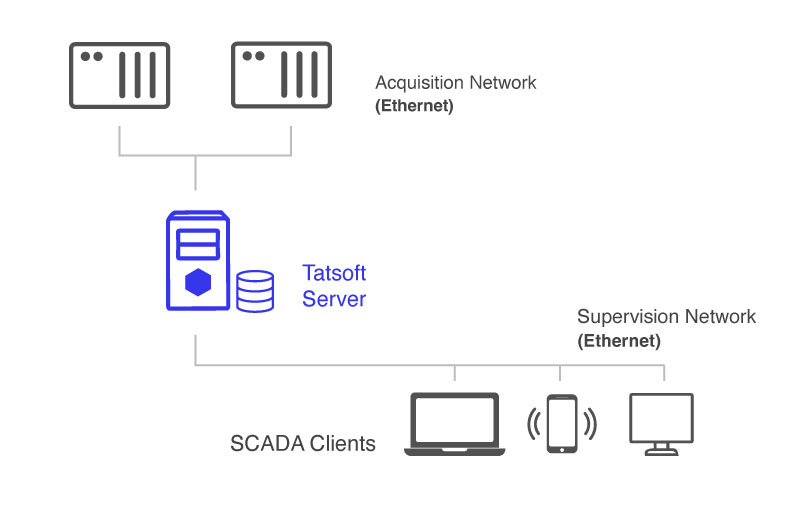

Single HMI to Server Based HMI

Of course the MachineHMI supports from one to many HMI stations. You can have stand alone to centrally managed and everything in between – Open and Flexible. Centrally managed for applications that require plant or enterprise wide development, standardization, deployment and maintenance.

Thin and Remote Access and Control

Full secure access if enabled. Access your remote HMI or network of HMIs, our Tatsoft Web Client can be used to develop virtual views with full graphics. Ideal for isolated facilities or HMI stations and you can interact with the site without physically visiting. Full access includes the development environment.

MachineHMI: Modern Human Machine Interface Software

Alarms and Notification

Multi-threaded alarming, log to SQL, scripts subscribe to events.

Built-In Drivers

Major PLC, OPC UA, MQTT drivers included. Toolkit for any protocol.

Dashboard Builder

Build dashboards and connect to data as part of your HMI.

Built-In SQL

Embedded SQL engine included or integrate to any SQL.

SQL Historian

Use built-in SQL or log to any Process Historian or Cloud Base Data Source.

SQL Data Logging

Comes with HMI just configure tag to log, rate or on event and go.

Intrinsically Secure

Implemented at the core of the platform, stable and secure.

Audit Trail Anything

Log events, you choose events to log to SQL and displayed in Audit window.

Symbols and Components

Tag, asset, template based, reusable components.

Robust and Fast

.NET to the core, Fast and Flexible Graphics.

Scripting

Code behind and expressions using VB.NET, C#, HTML5/ Javascript and Python.

Universal Connectivity

Secure connectivity included, build server or cloud connected HMIs.

Complete & Multi-Platform

Everything you need to build next gen HMIs, run on Windows or Linux.

Scalable HMI I/O Pricing

Buy what you need.

Redundancy

Server, device communications easily configured for redundancy.

FAQ

HMI software (Human Machine Interface software) is the layer that allows operators and engineers to visualize, monitor, and control industrial systems in real time. It converts complex machine data into intuitive graphics and dashboards. In industrial automation, HMI software improves situational awareness, reduces downtime, and enhances productivity by making data accessible and actionable. Tatsoft’s HMI solutions go beyond visualization — they are built on a modern .NET 8 framework that integrates with SCADA, MES, and IIoT applications within a single platform.

HMI software connects to industrial controllers, PLCs, and sensors to gather and display process data. Operators interact through screens, panels, or mobile devices to control and monitor equipment. Tatsoft HMI software (MachineHMI) connects natively to a wide range of devices and protocols — including Modbus, OPC UA, MQTT, and REST APIs — enabling secure connectivity from the edge to the enterprise. This flexibility ensures that engineers can design and deploy responsive interfaces across PCs, embedded devices, and web or mobile clients.

Modern human-machine interface software offers advanced visualization, multi-platform access, and seamless integration with industrial data systems. Key features include real-time data trending, alarm management, scripting in Python, and scalable architectures for distributed environments. Tatsoft’s FrameworX platform adds unique capabilities such as unified namespace integration, .NET-based performance, and built-in redundancy — giving users the flexibility to design anything from a simple operator panel to a full enterprise HMI/SCADA system.

When choosing HMI software, companies should evaluate compatibility with existing PLCs and protocols, scalability for future expansion, and the ease of creating and maintaining graphical displays. Support, licensing flexibility, and security compliance are also essential. Tatsoft HMI software is designed to scale from single-machine HMIs to enterprise-wide visualization systems — all within the same platform. Its unified development environment simplifies configuration, while Tatsoft’s technical team provides expert guidance through deployment and lifecycle management.

Security is critical for any HMI software used in industrial control systems. Key measures include user authentication, role-based access, data encryption, and secure communication with PLCs and field devices. Tatsoft implements industry-standard cybersecurity practices, supporting Windows authentication, TLS encryption, and redundant communication paths. Built on modern Microsoft .NET technology, Tatsoft HMI software ensures compliance with IT security standards and reliable operation across distributed environments.

Migrating to Tatsoft HMI software is straightforward thanks to the platform’s flexible architecture and conversion tools. Tatsoft provides import utilities for tags, screens, and scripts from legacy HMI or SCADA systems, significantly reducing redevelopment time. Because FrameworX supports standard protocols like OPC UA, MQTT, and Modbus, existing device connections can be reused without major reconfiguration. Tatsoft’s engineering team also offers migration support to ensure a smooth transition and immediate productivity gains with a modern, unified interface.

Unlike traditional HMIs that focus only on local visualization, Tatsoft HMI software is part of the full FrameworX platform — unifying HMI, SCADA, MES, and IIoT capabilities in a single environment. Built on .NET 8, it delivers high performance, cross-platform deployment, and unlimited scalability. Tatsoft eliminates the need for multiple software layers by combining real-time data acquisition, logic processing, and visualization, giving users a true modern SCADA and HMI foundation.

Tatsoft HMI software supports seamless connectivity with existing automation infrastructure. It communicates directly with PLCs, sensors, and industrial devices using drivers for Allen-Bradley, Siemens, Modbus, OPC UA, MQTT, and others. Integration is configured graphically, without complex scripting, allowing engineers to quickly connect real-time data streams to dashboards and alarms. This interoperability makes Tatsoft ideal for brownfield upgrades and mixed-technology environments.

Tatsoft HMI software is used across multiple industries including manufacturing, energy, water treatment, building automation, and OEM machine control. Its flexibility and open architecture make it suitable for discrete, batch, and continuous processes. OEMs and system integrators embed Tatsoft HMIs into their equipment, while enterprises deploy it for plantwide operations — leveraging the same platform for visualization, SCADA, and MES integration.

Tatsoft offers flexible licensing for its HMI software to accommodate System Integrators, OEMs, machine builders, and enterprise users. You can check out our full pricing here.