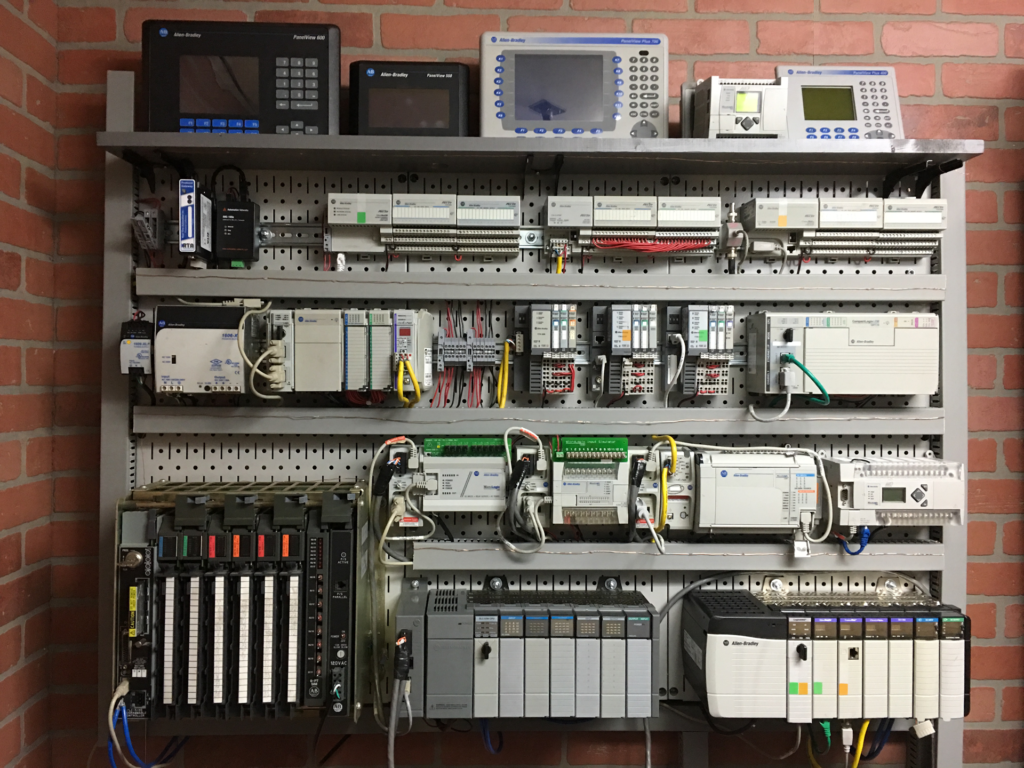

As a control systems integrator, you transform complex technology into business value for your industrial clients. Today, this means helping those clients capitalize on the many opportunities presented with Industry 4.0 by using flexible real-time software for human-machine interface (HMI) or SCADA applications.

Don’t settle for “good enough” or legacy software. Technology is evolving. You can help your customers keep up by recommending and implementing an open modern software platform.

These are the five attributes any future-thinking HMI/SCADA software platform you offer must possess.

1) Your software must possess industrial DNA

Do the options on your shortlist have industrial DNA? Software with industrial DNA possesses two unique qualities.

First, software with industrial DNA is built from the ground up by a company with a deep history in industrial automation. Industrial software automation platforms must smoothly interface between humans and machines. This way, humans can easily understand the data machines generate and operationalize it. This “dialogue” is best facilitated by software companies that understand the language and requirements of industrial environments like oil and gas facilities or gas plants.

Second, software with industrial DNA is designed with engineers in mind. This means it can be customized to keep up with your clients’ future digital transformation needs.

2) Your software must be open and flexible

As your clients’ businesses evolve, they need more real-time data analytics to advance. The HMI/SCADA software you select must have the features and functionality to keep up with these business realities. The software you use must offer:

- Standard SQL for database and configuration tables

- Universal connectivity through a dedicated server or connectivity to the cloud

- XAML to create customized, user-friendly interfaces based on business needs

- Diverse scripting capabilities including VB.NET, C#, HTML5, Javascript, and Python

- A wide range of communication interfaces that leverage the Windows Communication Foundation (WCF), JSON (JavaScript Object Notation), and web services

- Support for OPC Foundation standards and MQTT (e.g. SparkplugB)

- Built-in drivers for PLCs and industrial protocols within the application

3) Your software must easily connect and integrate with SQL

Your chosen HMI/SCADA solution must easily integrate with SQL to other enterprise resources. Today’s enterprises are striving for operational excellence through integrated data and automation. The first step towards this goal is eliminating silos and ensuring connectivity between different units. Above all, there must be a clear flow from operational technology (OT) to information technology (IT) and vice versa. This way, your clients can obtain a clear picture of their data.

When selecting your chosen tool, ensure it offers built-in connectivity through:

- NoSQL

- Leading process historians from OSISoft

- GE

- WW

It should also offer built-in integration to public clouds, such as Azure, AWS, and Google Cloud, as well as private clouds.

4) Your software must be ready for the opportunities and challenges of Industry 4.0

Can your chosen software keep up with the demands of the Industrial Internet of Things (IIoT)? While IIoT presents many opportunities such as reduced downtime through predictive maintenance and data-driven business analytics, it also introduces challenges:

- Managing and interpreting the large amounts of IIoT data produced before it becomes stale

- Ensuring fast and reliable connectivity and networking

- Ensuring up-to-date and comprehensive cybersecurity to protect a wide range of connected devices

Your selected HMI/SCADA software should be able to account for an exploding number of connected devices, machinery, and incoming data and support emerging IoT tools and concepts like digital twins. IT should also provide an intuitive, graphic-rich interface to prevent cognitive overload for end users.

5) Your software must support multiple programming languages and environments

Finally, your chosen software must be versatile enough to keep pace with changing business demands, requirements, and environments. It should empower internal experts to engineer the customized, business solutions they need. To do this, the HMI/SCADA solution you deliver to your clients should support languages like VB.NET, HTML5, Javascript, and Python. It should also be able to run on multiple platforms, such as Windows and Linux.

Empower your clients with flexible HMI/SCADA built for Industry 4.0

Usability impacts how your clients receive the solutions you engineer. A powerful HMI with the right features ensures your clients obtain long-term business value and make the most of Industry 4.0