SCADA Software for Oil and Gas

Empowering operational data access and integration from the well to the cloud

FrameworX Solutions for Oil & Gas

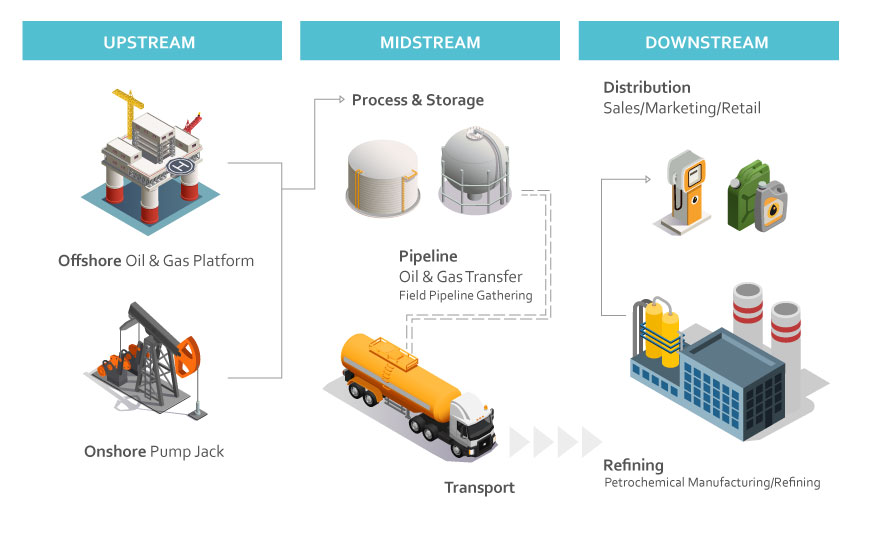

Tatsoft’s FrameworX Platform is an innovative and affordable Industrial IoT and modern SCADA software for Oil & Gas, built on a modern .NET foundation and unified by design. The platform allows enterprises to integrate, process, and visualize critical operational information across upstream, midstream, and downstream operations.

FrameworX enables real-time data connections that help operators capture unstructured information and produce structured insights for better decision-making, improved productivity, and efficiency. FrameworX is a state-of-the-art, agnostic, non-intrusive, and scalable technology that supports seamless real-data integration across legacy automation systems and modern IIoT architectures.

With fully integrated development tools to build SCADA/HMI and IIoT solutions, FrameworX scales from edge to enterprise — right-sized to unlimited — using one unified platform.

Connectivity, Standards, and IIoT Interoperability

FrameworX uses open, industry-standard technologies such as OPC UA, MQTT/Sparkplug B, and WITSML—critical for interoperability in Oil & Gas SCADA systems. Its open architecture ensures secure, reliable data exchange with any PLC, RTU, SCADA, Historian, or UNS environment.

This provides Oil & Gas operators with a unified, future-ready foundation for drilling, production, SCADA modernization, and pipeline operations.

Key Benefits of Using FrameworX SCADA Software for Oil & Gas

- Faster Decision-Making: Real-time data and remote control support rapid operational adjustments.

- Cost-Effective Modernization: Augment and enhance existing SCADA systems without replacement.

- Greater Operational Efficiency: Remote access and control of geographically distributed wells, pipelines, and assets.

- Improved Safety: Proactive alarm management helps maintain safe and responsible operations.

- Higher Uptime: Faster response times and remote visibility reduce unplanned downtime.

- Optimized Back-Office Workflows: Automated calculations and reporting reduce manual administrative tasks.

FrameworX improves productivity and efficiency for Oil & Gas SCADA operations, from well performance to pipeline management.

Oil & Gas Applications Enabled by FrameworX

- Real-time drilling optimization with streaming-data analytics and AI

- Well monitoring with advanced visualization for OSIsoft AF and EF

- Secure supervisory control (SCADA + LACT + remote operations)

- Pipeline SCADA reporting, alarms, and historian integration

- SCADA architecture modernization for pipeline and facilities

- Remote asset monitoring with ESRI maps and intelligent alarms

- IIoT cloud integration—Microsoft Azure and edge data delivery

From Upstream to Downstream

Real-Time Information

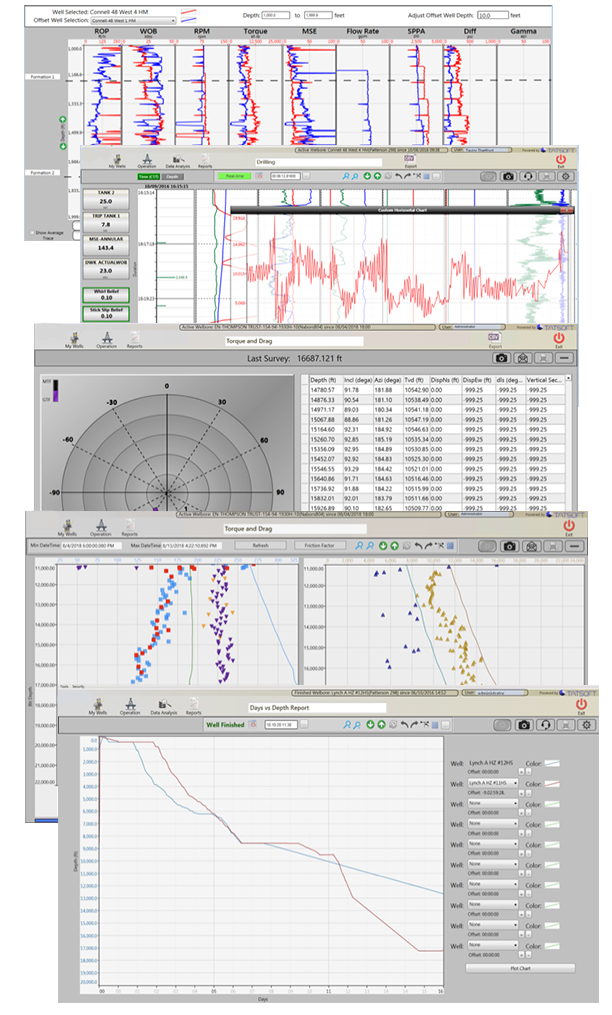

Apache needed a modern yet affordable solution to improve well performance in the Permian Basin through real-time operational data. They also required secure remote access for faster decisions.

Apache selected FrameworX as their IoT and integration engine to aggregate, process, and visualize real-time data. FrameworX’s open standards and native interfaces to SCADA and Historian systems allowed Apache to stream well data to analytics dashboards accessible from office or field.

Deploy Anywhere: Edge, Cloud, or Control Room

- Desktop, Web, Mobile, Edge

- Windows, Linux, iOS, Web, Raspberry Pi

- Build once using the unified Designer

- Deploy across distributed environments

This flexibility makes FrameworX one of the most adaptable SCADA software solutions for oil and gas operations.

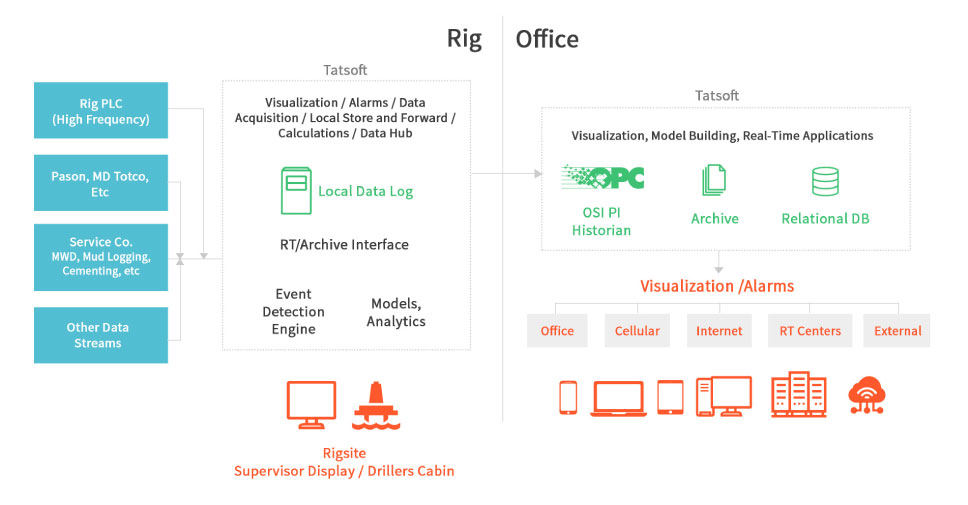

Deep-Sea Drilling – High-Performance SCADA Visualization

FrameworX was selected to power the user interface for a deep-sea drilling project with ~40 displays, real-time collaboration using Trend Annotations, and high-frequency data processing:

- ~5,000 channels per second

- ~500 channels every 100ms

- Integration with National Instruments and OSIsoft systems

This use case highlights the performance and scalability needed for offshore SCADA systems.

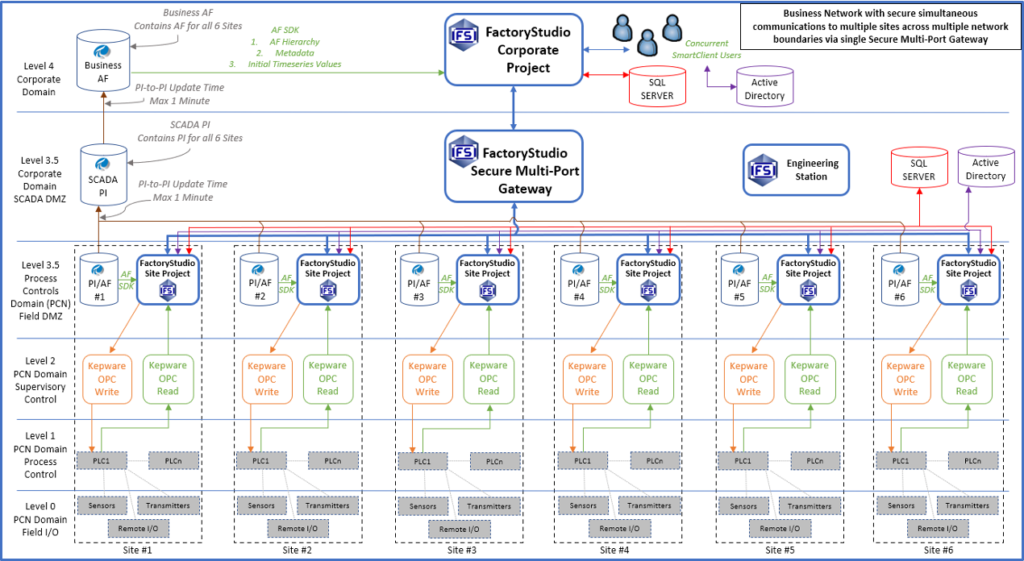

Command & Control – Secure SCADA Gateway

This company needed a solution for multiple applications to provide secure, auditable, access to remote operations, augmenting the existing OSISoft and Rockwell PLC architecture. FrameworX built-in secure gateway, full operator audit trail, and flexible interfaces to PI AF, OPC UA was the ideal fit.

Challenge:

- A number of Applications or services at Bus. Network required access to the process control network

- Each Application or service needed a “hole” in the firewall to operate correctly

- Too many holes in firewall makes the process control network vulnerable

- Needed Audit trail of data feed to identify When & Who modified it

Solution that FrameworX provided:

- A Control Dashboard to direct traffic through Tatsoft’s secure gateway to the process control network which is capable to direct and stop flow of data selectively as per User Defined Business Rules

- Data Authenticated & Authorized, Eliminate Multiple holes in Firewall

- Audit trail of manipulated data

- Multiple Applications or User’s requirements to access process control network was analyzed based on Business case

- Requirements converted into Dataset and selection on dataset made at BUS Level

OEM in Oilfield Services

OEM focused on providing performance enhancing solutions that meet the strictest safety standards. They deliver enhanced mud pump components, top drives, mud valves, RCD/MPD systems, shaker screens and other drilling products that decrease downtime, improve safety and perform in the toughest drilling environments. The OEM solution can be customized based on well complexity and risk tolerance.

Features include:

- System & Operator Station suitable for installation in C1D1 area

- Optional flow meter for event monitoring and influx, or loss detection

- Electrically actuated for accuracy and speed

- Functionalities include static position, pressure or dynamic pressure control (automated connection schedule)

- Simple dashboard interface that is easy to learn and operate.

- System configuration requires minimal training – no calibration expert needed

- Wellbore model for accurate downhole pressure control

Remote Asset Monitor

Our Asset Monitor solution is a template application created on top of FactoryStudio, allowing the easy implementation of custom corporate applications to monitor and audit operations of remote assets.

Our Asset Monitor solution template project is based on several customer solutions to give you a quick start for your project. It includes:

- Assets Overview Page

- Advanced Trend and Annotations View

- Alarms, Events, and Notifications Engine

- Reports and Dashboard Builder

- Of course, the entire FrameworX Platform development tools

RigDAP – Real-Time Drilling Data Monitoring

Tatsoft’s solution for Drilling Data Aggregation is called RigDap, in combination with our partner, Intellicess and their technology Sentinel RT ™, an A.I. backend engine able to perform real-time streaming-data analysis, allows you to truly own your data so you can perform analysis in a reliable, consistent and controlled way.